Product Overview

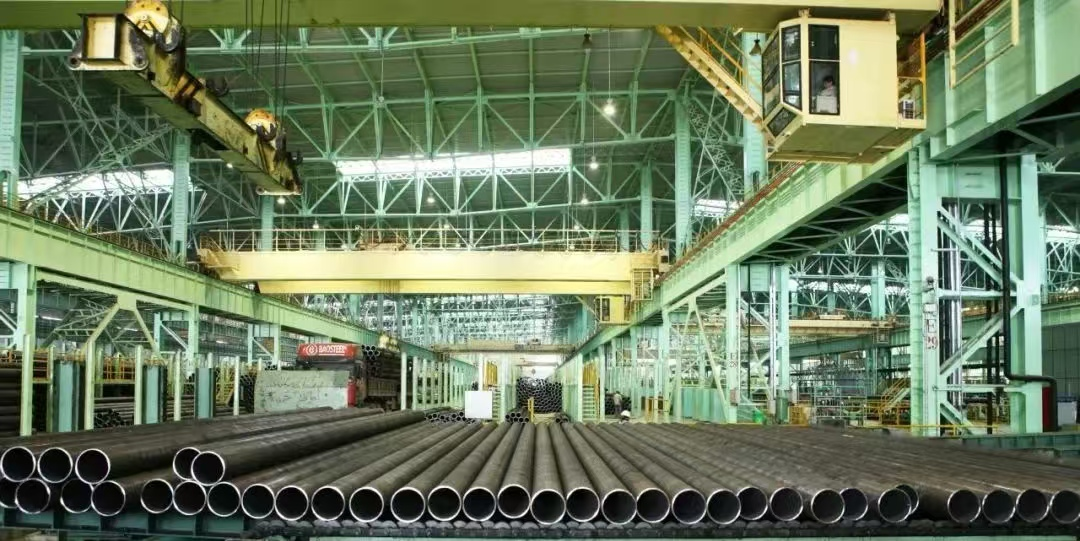

Womic Steel is a trusted manufacturer and global supplier of API 5L Grade X65M PSL2 steel pipes. Our products are engineered for use in high-performance pipeline projects across oil, gas, petrochemical, and water transportation sectors. With full compliance to the API 5L 45th Edition standard and additional rigorous internal standards, Womic Steel delivers steel pipes that combine mechanical strength, weldability, and long-term corrosion resistance.

API 5L X65M PSL2 is a high-strength, thermomechanically rolled steel pipe, ideal for both onshore and offshore installations. Womic Steel produces both Seamless and SAWL (Longitudinal Submerged Arc Welded) pipes.

Dimensions

- Outer Diameter (OD): 20" – 56" (508 mm – 1422 mm)

- Wall Thickness: 6 mm – 40 mm (customizable)

- Length: 12.0 m ± 100 mm standard; fixed lengths available

- Pipe Ends: Beveled as per ASME B16.25 or square cut for coating

Chemical Composition (Max %)

- Carbon (C): ≤ 0.18

- Manganese (Mn): 1.00 – 1.45

- Phosphorus (P): ≤ 0.020

- Sulfur (S): ≤ 0.010

- Silicon (Si): ≤ 0.45

- Niobium (Nb): ≤ 0.05

- Vanadium (V): ≤ 0.10

- Titanium (Ti): ≤ 0.04

- Chromium (Cr): ≤ 0.50

- Nickel (Ni): ≤ 0.50

- Copper (Cu): ≤ 0.50

- Molybdenum (Mo): ≤ 0.10

- Aluminum (Al): ≤ 0.06

Carbon Equivalent (CEIIW): ≤ 0.43 calculated per ISO 21466.

Mechanical Properties

- Yield Strength: ≥ 450 MPa (maximum 600 MPa)

- Tensile Strength: 535 – 760 MPa

- Elongation: ≥ 20%

- Charpy Impact Energy: ≥ 60 J average at -40°C (base metal, weld, and HAZ)

- Hardness: ≤ 250 HV10

- Flattening, Bending, and Guided Bend Tests: Conducted per API 5L PSL2

Manufacturing & Testing Process

- Forming: UOE, JCOE, or 3-roll bending for SAWL; hot rolling for seamless

- Welding: Internal and external submerged arc welding (SAW)

- Heat Treatment: Thermomechanical rolling or post-weld heat treatment with full traceability

- Hydrostatic Test: 100% hydrostatic testing at ≥ 95% SMYS

- Non-Destructive Testing (NDT): Ultrasonic, Radiographic, Magnetic Particle, and Penetrant Testing

- Dimensional Inspection: 100% for OD, WT, roundness, straightness, and length

Dimensional Tolerances

- OD Tolerance: ±0.75% or ±0.5 mm

- Wall Thickness: -0 / +10%

- Length Tolerance: +100 / -0 mm

- Straightness: Max deviation ≤ 0.2% of length

- End Squareness: ≤ 1.5 mm deviation

External 3LPE Coating (Optional)

Womic Steel offers pipes with high-performance 3-Layer Polyethylene (3LPE) external coating for corrosion protection.

- Layer 1: Fusion Bonded Epoxy (FBE), min 100 μm

- Layer 2: Adhesive Copolymer

- Layer 3: Polyethylene, thickness 2.0–2.5 mm

- Total Coating Thickness: ≥ 2.5 mm

Coating Tests: Holiday test (25 kV), adhesion, impact, indentation, and cathodic disbondment.

Marking & Traceability

- Stamped or inkjet-printed prior to coating

- Includes: Grade, Spec, Size, Heat No., Batch No., Manufacturer ID

- Barcoded labels for digital traceability and inventory control

Packaging & Shipping

- Ends: Protected with plastic caps

- Bundled with steel straps and wooden spacers

- Export-standard seaworthy packaging

- Anti-roll blocking and foam-lined for bulk shipments

- Global delivery via container, vessel, or multimodal freight

Certifications & Compliance

- API 5L Monogram License

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management

- ISO 45001:2018 Occupational Health & Safety

- CE (PED 2014/68/EU) upon request

- Third-party inspection by SGS, BV, DNV, TUV available

Applications

- Long-distance oil and gas transmission pipelines

- High-pressure water transport systems

- Petrochemical and refinery piping

- Slurry pipelines in mining operations

- Marine and offshore structural pipelines

Production Lead Time

- Standard production cycle: 25–40 days

- Monthly production capacity: Over 5,000 tons

- Pre-booked raw material inventory for fast-track orders

Womic Steel Advantages

- Full compliance with API 5L and client-specific specifications

- Integrated SAWL and 3LPE coating lines for total quality control

- Dedicated engineering and R&D support team

- Advanced inspection labs for destructive and NDT testing

- Direct shipping access and freight optimization

- Competitive pricing with uncompromised quality and service

Choose Womic Steel Group as your reliable partner for SMLS Steel Pipes,Fittings and unbeatable delivery performance. Welcome Inquiry!

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Post time: Apr-17-2025