ASTM A182 Forged or Rolled Alloy-Steel Flanges, Forged Fittings, and Valves

ASTM A182 is an essential specification for forged or rolled alloy-steel flanges, forged fittings, and valves designed for use in high-temperature, high-pressure environments. This standard provides guidelines for the chemical composition, mechanical properties, testing methods, and other essential factors that ensure the durability and reliability of these components in critical applications.

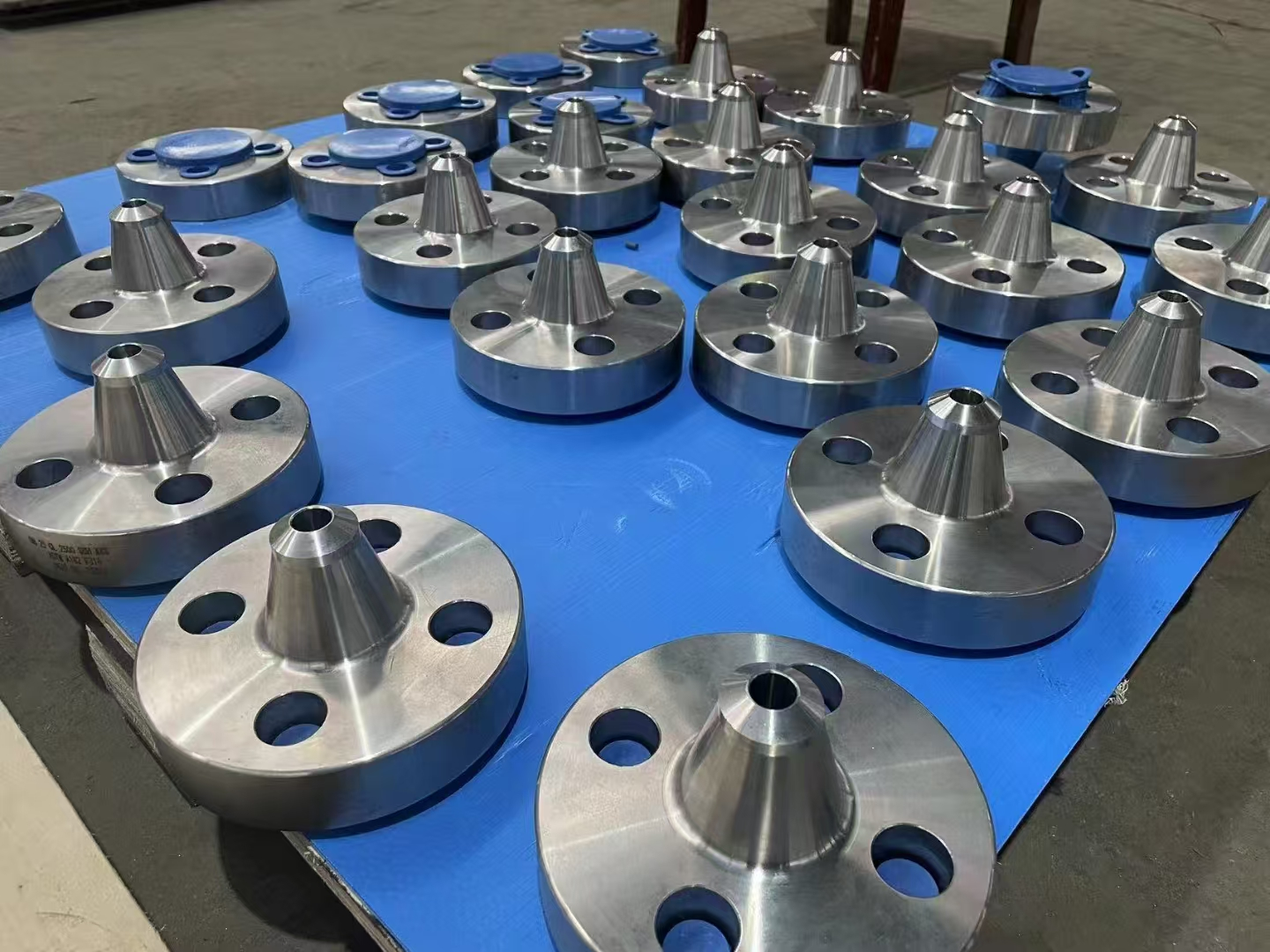

At Womic Steel, we manufacture a wide range of products adhering to the ASTM A182 standard, offering superior quality and precision. In this article, we will explore the key elements of this standard and showcase Womic Steel's production capabilities and the advantages of choosing us as your supplier.

Types of Products Covered by ASTM A182

ASTM A182 covers various forged or rolled steel components, including:

1. Flanges – These are used to connect pipes, valves, pumps, and other equipment in a piping system.

2. Forged Fittings – These include elbows, tees, reducers, caps, and unions used in high-pressure systems.

3. Valves – Designed for controlling the flow of fluids in high-temperature environments.

4. Other Forged or Rolled Products – These include valves and fittings used in steam, gas, and other high-pressure systems.

At Womic Steel, we produce these items in various sizes, materials, and configurations, ensuring they meet your specific application needs.

Materials and Chemical Composition

The ASTM A182 standard specifies several material grades, including carbon steel, low alloy steel, and stainless steel, each with distinct chemical composition requirements. Here are some of the key materials covered under ASTM A182:

1. Grade F1 – Carbon steel with a composition that allows it to perform in moderate temperatures.

2. Grade F5, F9, F11, F22 – Low alloy steels designed to withstand higher temperatures and pressures.

3. Grade F304, F304L, F316, F316L – Austenitic stainless steels, widely used for their corrosion resistance in various chemical processing environments.

For each grade, the chemical composition is meticulously controlled to meet stringent ASTM requirements. Below are the details for each material's chemical composition and mechanical properties.

Chemical Composition and Mechanical Properties

1. Grade F1 - Carbon Steel

Chemical Composition:

Carbon (C): 0.30-0.60%

Manganese (Mn): 0.60-0.90%

Silicon (Si): 0.10-0.35%

Sulfur (S): ≤ 0.05%

Phosphorus (P): ≤ 0.035%

Mechanical Properties:

Tensile Strength (MPa): ≥ 485

Yield Strength (MPa): ≥ 205

Elongation (%): ≥ 20

2. Grade F5 - Low Alloy Steel

Chemical Composition:

Carbon (C): 0.10-0.15%

Manganese (Mn): 0.50-0.80%

Chromium (Cr): 4.50-5.50%

Molybdenum (Mo): 0.90-1.10%

Sulfur (S): ≤ 0.03%

Phosphorus (P): ≤ 0.03%

Mechanical Properties:

Tensile Strength (MPa): ≥ 655

Yield Strength (MPa): ≥ 345

Elongation (%): ≥ 20

3. Grade F304 - Austenitic Stainless Steel

Chemical Composition:

Carbon (C): ≤ 0.08%

Manganese (Mn): 2.00-2.50%

Chromium (Cr): 18.00-20.00%

Nickel (Ni): 8.00-10.50%

Sulfur (S): ≤ 0.03%

Phosphorus (P): ≤ 0.045%

Mechanical Properties:

Tensile Strength (MPa): ≥ 515

Yield Strength (MPa): ≥ 205

Elongation (%): ≥ 40

4. Grade F316 - Austenitic Stainless Steel (Corrosion Resistant)

Chemical Composition:

Carbon (C): ≤ 0.08%

Manganese (Mn): 2.00-3.00%

Chromium (Cr): 16.00-18.00%

Nickel (Ni): 10.00-14.00%

Molybdenum (Mo): 2.00-3.00%

Sulfur (S): ≤ 0.03%

Phosphorus (P): ≤ 0.045%

Mechanical Properties:

Tensile Strength (MPa): ≥ 515

Yield Strength (MPa): ≥ 205

Elongation (%): ≥ 40

Mechanical Properties and Impact Requirements

Mechanical properties such as tensile strength, yield strength, and elongation are critical for ensuring that the forged components perform reliably under pressure. ASTM A182 specifies these properties for each material grade, with requirements varying based on the application conditions.

Impact testing is another critical component of the standard, ensuring that the forged parts can withstand sudden changes in temperature or impact. For example, the standard may require a Charpy V-notch test to ensure toughness in low-temperature conditions.

Production Processes and Heat Treatment Requirements

Womic Steel follows stringent production processes to ensure that all ASTM A182 products meet the highest quality standards. This includes:

Forging and Rolling – Our state-of-the-art machinery ensures that each part is forged or rolled to precise dimensions and tolerances.

Heat Treatment – Heat treatment is critical for achieving the desired mechanical properties. ASTM A182 requires specific heat treatment cycles depending on the material grade, such as annealing, quenching, and tempering to improve toughness and strength.

Welding – We provide custom welding solutions for ASTM A182 products, ensuring reliable, leak-proof connections. Welding procedures are carefully controlled to ensure that welded parts meet or exceed the strength of the base material.

Inspection and Testing

We conduct comprehensive inspection and testing to verify that all products meet the ASTM A182 standard. This includes:

Visual Inspections – For surface defects or imperfections.

Non-Destructive Testing (NDT) – Including ultrasonic testing and radiographic inspection to detect internal flaws.

Mechanical Testing – Tensile strength, yield strength, and impact testing to confirm the material's performance under stress.

Chemical Analysis – Ensuring that the chemical composition adheres to the standard's specifications.

All our products undergo strict quality control procedures, and we provide detailed certificates of compliance for every order.

Product Specifications and Size Range

At Womic Steel, we offer a wide range of ASTM A182 products in various sizes and specifications. Our size range includes:

Flanges: From 1/2" to 60" in diameter.

Forged Fittings: From 1/2" to 48" in diameter.

Valves: Custom sizes to suit your system requirements.

Our products are available in different pressure ratings and materials, ensuring that we can meet the specific needs of your project.

Packaging, Shipping, and Transport Advantages

We understand the importance of timely and secure delivery. Womic Steel offers customized packaging that protects the integrity of the products during transit. Whether it’s through containerized shipping or specialized freight solutions, we ensure that your order arrives on time and in perfect condition.

Our transportation expertise and direct partnerships with shipping companies allow us to offer competitive rates and flexible shipping solutions.

Customization and Additional Services

In addition to our extensive range of standard products, Womic Steel offers custom manufacturing for unique requirements. We can modify dimensions, materials, and finishes to suit your specific application.

Processing Services include:

Machining – For precise adjustments to fit your requirements.

Welding – For customized flange connections or fittings.

Coatings and Anti-Corrosion Services – Providing long-lasting protection based on your environmental requirements.

Why Choose Womic Steel?

Production Capacity: We have state-of-the-art manufacturing facilities with high output capabilities.

Technical Expertise: Our team consists of highly skilled engineers and technicians committed to producing high-quality products.

Supply Chain Advantage: We have strong relationships with raw material suppliers, ensuring timely delivery and cost advantages.

Customization Options: We offer flexible solutions to meet specific project requirements, including welding, machining, and coating.

Conclusion

The ASTM A182 standard ensures the reliability and performance of forged and rolled steel products in critical applications. Womic Steel is your trusted partner for high-quality products manufactured to this standard, offering comprehensive support from technical specifications to logistics. Whether you need custom sizes, welding, or specialized coatings, we provide tailored solutions to meet your needs, ensuring superior performance and delivery reliability.

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Post time: Apr-21-2025