ASTM A335 Grade P9 alloy steel pipe is a chromium-molybdenum alloy steel pipe specifically developed for high-temperature and high-pressure service. As one of the most widely applied Cr-Mo alloy grades, ASTM A335 P9 plays a critical role in power generation, petrochemical processing, refinery piping systems, boilers, and heat transfer equipment.

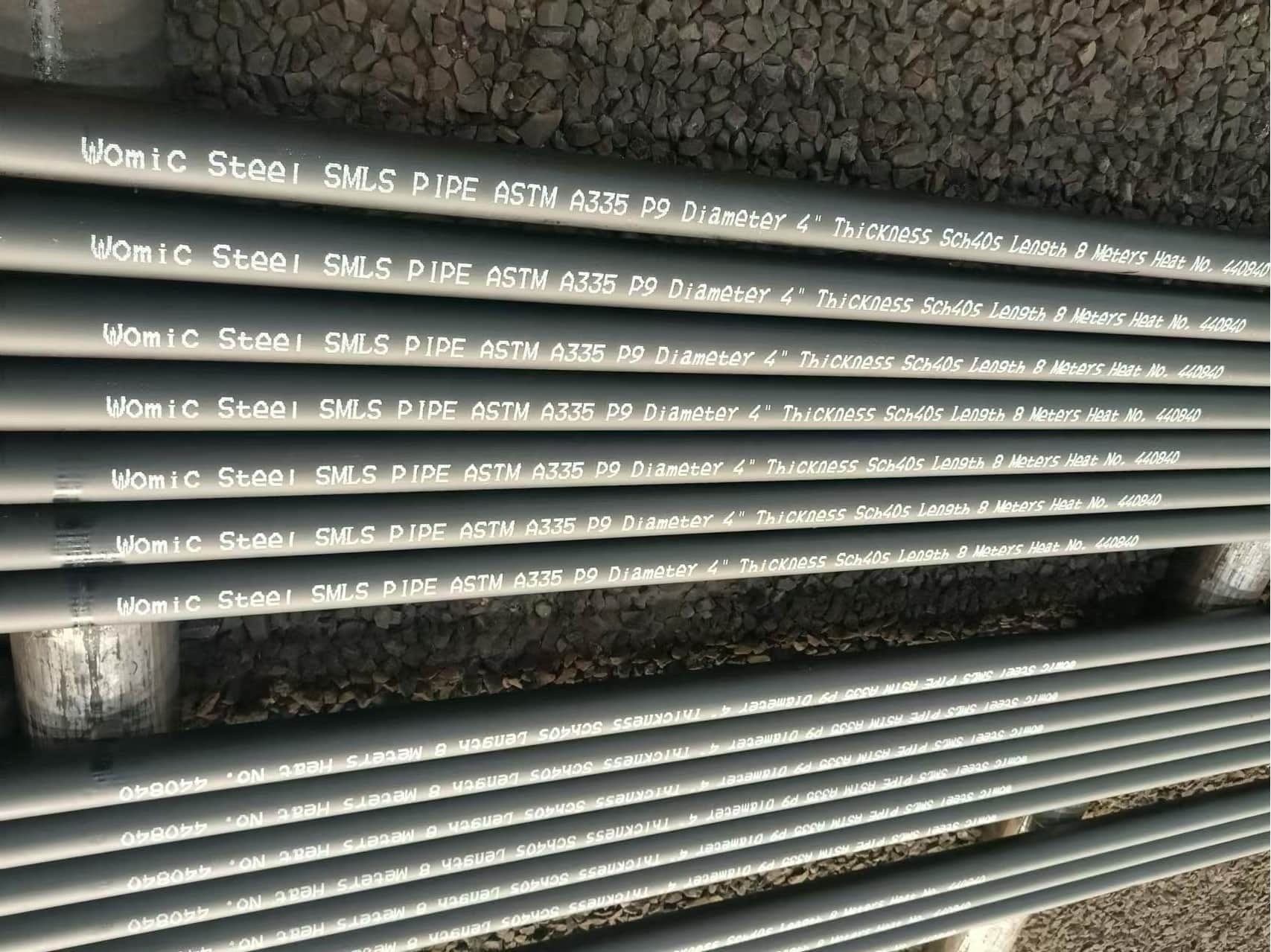

As an experienced manufacturer and exporter, Womic Steel specializes in the production and supply of ASTM A335 P9 seamless alloy steel pipes, offering stable quality, full compliance with ASTM A335 requirements, and fast delivery supported by regular stock of common sizes.

1. Standard Background and Position of ASTM A335 P9

ASTM A335 is the standard specification covering seamless ferritic alloy steel pipe intended for high-temperature service. Within this standard, ASTM A335 Grade P9 is defined by its nominal chemical composition of approximately 9% Chromium and 1% Molybdenum, which distinguishes it from lower alloy grades such as P5 or P11.

Compared with carbon steel pipes, ASTM A335 P9 alloy steel pipe offers significantly enhanced oxidation resistance, creep strength, and thermal stability. Compared with lower chromium alloy grades, A335 P9 provides improved resistance to scaling and microstructural degradation at elevated temperatures.

2. Typical Applications of ASTM A335 P9 Alloy Steel Pipe

ASTM A335 P9 pipes are primarily selected for systems operating under continuous high temperature and pressure, where long-term reliability is essential.

Common applications of ASTM A335 P9 alloy steel pipe include:

- Main steam pipelines in thermal and combined-cycle power plants

- Superheater and reheater piping systems

- High-temperature headers and manifolds

- Petrochemical and refinery process piping

- Heat exchangers exposed to elevated temperatures

- Pressure piping systems in chemical plants

In all these applications, ASTM A335 P9 is valued for its ability to maintain mechanical strength and dimensional stability during long-term exposure to heat.

3. Metallurgical Characteristics of ASTM A335 P9

The performance of ASTM A335 Grade P9 alloy steel pipe is closely related to its metallurgical design.

Chromium in A335 P9 enhances oxidation resistance and forms stable carbides that improve high-temperature strength. Molybdenum contributes to creep resistance and reduces the tendency for softening during prolonged service. Together, these alloying elements give ASTM A335 P9 alloy steel pipe excellent resistance to thermal fatigue and microstructural degradation.

Proper heat treatment is essential to fully develop these properties, making process control a critical factor in A335 P9 pipe manufacturing.

4. Manufacturing Process of ASTM A335 P9 Seamless Pipes

At Womic Steel, ASTM A335 P9 seamless alloy steel pipes are produced using a carefully controlled manufacturing route designed to meet both standard and project-specific requirements.

The production process typically includes:

l Selection of qualified alloy steel billets strictly matching ASTM A335 P9 chemistry

l Hot piercing to form hollow shells

l Hot rolling or hot extrusion to achieve target dimensions

l Precision sizing and straightening

l Mandatory heat treatment in accordance with ASTM A335

l Final inspection, testing, and marking

This seamless process ensures uniform wall thickness, excellent concentricity, and consistent mechanical properties across the entire length of the ASTM A335 P9 pipe.

5. Heat Treatment Requirements for ASTM A335 P9

Heat treatment is one of the most critical stages in the production of ASTM A335 Grade P9 alloy steel pipe.

According to ASTM A335, A335 P9 pipes are normally supplied in the normalized and tempered (N&T) condition. The normalizing process refines the grain structure, while tempering adjusts hardness and toughness to the required balance.

Correct heat treatment ensures that ASTM A335 P9 alloy steel pipe achieves:

l Stable tensile strength

l Adequate ductility

l Improved creep resistance

l Long-term microstructural stability at high temperature

Womic Steel strictly controls heating temperature, holding time, and cooling rate to guarantee consistent results for every batch of A335 P9 pipes.

6. Dimensional Range and Supply Capability

Womic Steel supplies ASTM A335 P9 seamless pipes in a wide dimensional range suitable for most industrial applications.

l Outside Diameter: from small-bore to large-diameter piping

l Wall Thickness: SCH series or customized thickness

l Length: random length, fixed length, or project-specific

Regular production and inventory planning allow Womic Steel to maintain stock of common ASTM A335 P9 pipe sizes, significantly reducing lead time for urgent requirements.

7. Quality Control and Inspection of ASTM A335 P9 Pipes

Quality assurance is embedded throughout the production of ASTM A335 P9 alloy steel pipes.

Inspection and testing include:

l Chemical composition analysis to confirm Cr and Mo content

l Tensile testing and hardness testing

l Hydrostatic testing or nondestructive testing (UT / Eddy Current)

l Dimensional inspection and visual examination

l Review of heat treatment records

Each shipment of ASTM A335 P9 pipe is supplied with Mill Test Certificates in accordance with EN 10204 3.1, ensuring full traceability.

8. Welding Compatibility and Fabrication Considerations

ASTM A335 P9 alloy steel pipe is commonly welded during installation. Due to its alloy content, proper welding procedures are essential.

Preheating, controlled interpass temperature, and post-weld heat treatment (PWHT) are typically required to maintain the integrity of A335 P9 piping systems. Womic Steel provides technical support regarding material behavior and fabrication considerations when supplying ASTM A335 P9 pipes for complex projects.

9. Delivery Advantage and Production Lead Time

One of Womic Steel’s key strengths is delivery reliability for ASTM A335 Grade P9 alloy steel pipe.

l Regular stock available for common sizes

l Fast-track production capability with lead time as short as 30 days

l Flexible scheduling for urgent project demands

This combination of inventory and production efficiency allows customers to shorten procurement cycles for ASTM A335 P9 pipes.

10. Packaging and Global Transportation

ASTM A335 P9 alloy steel pipes are packed with full consideration for corrosion protection and transportation safety.

l End caps for all pipes

l Bundled packing with steel straps or wooden supports

l Clear marking identifying ASTM A335 P9 grade and heat numbers

l Containerized or breakbulk shipment depending on size

Womic Steel’s logistics expertise ensures that ASTM A335 P9 pipes arrive at project sites in optimal condition.

11. Why Choose Womic Steel for ASTM A335 P9 Alloy Steel Pipes

l Specialized experience in ASTM A335 P9 alloy steel pipe manufacturing

l Strict compliance with ASTM A335 standard

l Full quality documentation and inspection control

l Stock availability and fast 30-day production capability

l Reliable global logistics and export support

We pride ourselves on our customization services, fast production cycles, and global delivery network, ensuring your specific needs are met with precision and excellence.

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Post time: Jan-19-2026