1. Product Overview

Womic Steel is a trusted manufacturer of high-quality copper pipes conforming to ASTM B88 standards, particularly the Type L specification made from C12200 (phosphorus-deoxidized, high residual phosphorus) copper. These rigid copper pipes are widely used in plumbing, HVAC, fire protection, gas, and general utility systems due to their excellent corrosion resistance, durability, and formability.

C12200 copper contains a high percentage of pure copper and a small amount of phosphorus, enhancing its weldability and resistance to hydrogen embrittlement. Type L pipes strike an ideal balance between wall thickness and weight, offering reliability in both aboveground and underground installations.

2. Production Range

- Outside Diameter (OD): 6 mm to 219 mm

- Wall Thickness (WT): 0.3 mm to 10 mm

- Length: Standard lengths of 3m, 5m, 6m, with customized lengths available upon request

- Coiled Tubes: Available in 25m or 50m coils for flexible installation in heat exchangers

- End Finish: Plain end, cleaned and deburred; available with or without caps

3. Dimensional Tolerances (ASTM B88 C12200 Copper Tubes)

Womic Steel ensures precise dimensional accuracy for C12200 tubes in compliance with ASTM B88 standards. The following tolerances apply:

ASTM B88 - Table 1: Dimensions, Weights, and Tolerances for Copper Water Tube Sizes

|

Nominal Size (in.) |

Outside Diameter (in.) |

OD Tolerance (Annealed) |

OD Tolerance (Drawn) |

Type K Wall (in.) |

Type K Tol. (in.) |

Type L Wall (in.) |

Type L Tol. (in.) |

Type M Wall (in.) |

Type M Tol. (in.) |

|

1/4 |

0.375 |

0.002 |

0.001 |

0.035 |

0.0035 |

0.03 |

0.003 |

C |

C |

|

3/8 |

0.5 |

0.0025 |

0.001 |

0.049 |

0.005 |

0.035 |

0.004 |

0.025 |

0.002 |

|

1/2 |

0.625 |

0.0025 |

0.001 |

0.049 |

0.005 |

0.04 |

0.004 |

0.028 |

0.003 |

|

5/8 |

0.75 |

0.0025 |

0.001 |

0.049 |

0.005 |

0.042 |

0.004 |

C |

C |

|

3/4 |

0.875 |

0.003 |

0.001 |

0.065 |

0.006 |

0.045 |

0.004 |

0.032 |

0.003 |

|

1 |

1.125 |

0.0035 |

0.0015 |

0.065 |

0.006 |

0.05 |

0.005 |

0.035 |

0.004 |

|

1 1/4 |

1.375 |

0.004 |

0.0015 |

0.065 |

0.006 |

0.055 |

0.006 |

0.042 |

0.004 |

|

1 1/2 |

1.625 |

0.0045 |

0.002 |

0.072 |

0.007 |

0.06 |

0.006 |

0.049 |

0.005 |

|

2 |

2.125 |

0.005 |

0.002 |

0.083 |

0.008 |

0.07 |

0.007 |

0.058 |

0.006 |

|

2 1/2 |

2.625 |

0.005 |

0.002 |

0.095 |

0.01 |

0.08 |

0.008 |

0.065 |

0.006 |

|

3 |

3.125 |

0.005 |

0.002 |

0.109 |

0.011 |

0.09 |

0.009 |

0.072 |

0.007 |

|

3 1/2 |

3.625 |

0.005 |

0.002 |

0.12 |

0.012 |

0.1 |

0.01 |

0.083 |

0.008 |

|

4 |

4.125 |

0.005 |

0.002 |

0.134 |

0.013 |

0.11 |

0.011 |

0.095 |

0.01 |

|

5 |

5.125 |

0.005 |

0.002 |

0.160 |

0.016 |

0.125 |

0.012 |

0.109 |

0.011 |

|

6 |

6.125 |

0.005 |

0.002 |

0.192 |

0.019 |

0.14 |

0.014 |

0.122 |

0.012 |

|

8 |

8.125 |

0.008 |

0.002/-0.004 |

0.271 |

0.027 |

0.2 |

0.02 |

0.17 |

0.017 |

|

10 |

10.125 |

0.008 |

0.002/-0.006 |

0.338 |

0.034 |

0.25 |

0.025 |

0.212 |

0.021 |

|

12 |

12.125 |

0.008 |

0.002/-0.006 |

0.405 |

0.04 |

0.28 |

0.028 |

0.254 |

0.025 |

A The average outside diameter of a tube is the average of the maximum and minimum outside diameter, as determined at any one cross section of the tube.

B Maximum deviation at any one point.

C Indicates that the material is not generally available or that no tolerance has been established

These tolerances ensure that the tubes meet high precision and quality requirements, making them suitable for demanding industrial and marine applications.

3. Chemical Composition (C12200 – ASTM B88)

Element Composition (% by weight)

Copper (Cu)MinB ≥ 99.9 (including silver)

Phosphorus (P) 0.015 – 0.040

A Oxygen shall be 10 ppm max.

B Copper + silvers ≤ 0.04

The phosphorus content improves weldability and resistance to stress cracking, while maintaining high thermal and electrical conductivity.

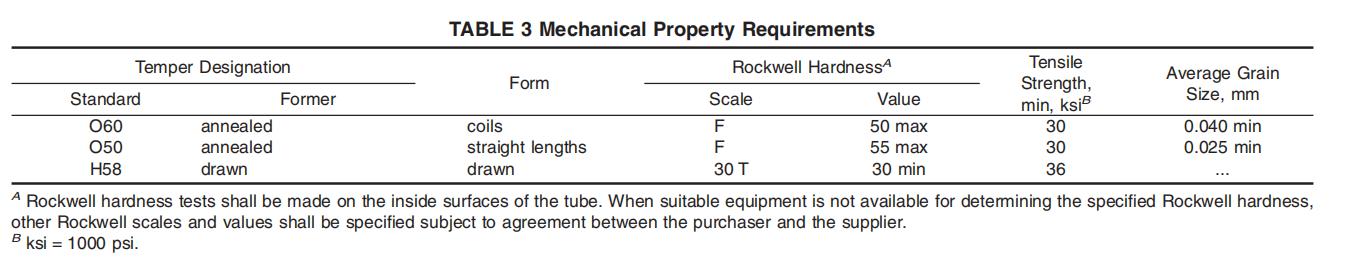

4. Mechanical Properties

Type L rigid copper pipe is typically supplied in a hard (drawn) temper, suitable for pressure systems and straight installations.

5. Delivery Conditions

Womic Steel delivers Type L copper pipes in the following conditions:

Hard Temper (H58): Straight lengths for pressure systems

Annealed Temper (O60):Available upon request for applications requiring bending and forming

6. Manufacturing Process

Womic Steel ensures high precision and quality through the following steps:

- Melting & Casting: High-purity copper is melted and cast into billets.

- Extrusion: Billets are extruded into tubular form.

- Cold Drawing: Tubes are drawn to final size and thickness.

- Annealing (optional): If required, heat-treated for soft temper.

- Straightening & Cutting: Pipes are cut to standard or custom lengths.

- Cleaning & Inspection: Internal and external surfaces are cleaned and checked.

- Marking & Packaging: Pipes are marked with ASTM B88, type, and size for traceability.

7. Testing & Inspection

Womic Steel ensures the highest quality standards by conducting rigorous testing and inspection, including:

- Chemical Composition Analysis: Verification using spectrographic or wet chemical analysis

- Tensile Testing: Ensuring strength and elongation meet ASTM B88 requirements

- Hardness Testing: Measured using the Vickers method

- Drift Expanding Test: Expansion of the tube end by 30% using a 45° conical mandrel

- Flattening Test: Assessment of deformability and resistance to cracking

- Eddy Current Test (ECT): Detection of surface and subsurface defects

- Hydrostatic Pressure Test: Ensuring tubes withstand internal pressure without leakage

8. Sampling

Sampling and testing are carried out according to ASTM B88 and internal QA protocols. Test samples are randomly selected from each lot for:

l Chemical content

l Mechanical properties

l Dimensional accuracy

l Surface condition

9. Packaging

To ensure safe handling and transportation, Womic Steel provides robust packaging solutions, including:

- Anti-Oxidation Coating: Protective layer applied to prevent corrosion during storage and transit

- End Caps: Plastic or metal caps on tube ends to prevent contamination

- Bundling: Secure strapping with plastic or steel bands for stability

- Wooden Crating: Packed in moisture-resistant wooden crates with protective foam lining

- Labeling: Each bundle is labeled with OD, WT, length, temper, batch number, and manufacturing date

10. Transportation & Logistics

Womic Steel ensures timely and secure delivery through:

- Sea Freight: Secure containerized shipping for global distribution

- Rail & Road Transport: Reliable delivery for regional customers

- Special Handling: Climate-controlled options for sensitive applications

- Comprehensive Documentation: Including Mill Test Certificates (MTC), Material Compliance Reports, and Insurance

- Superior Corrosion Resistance: Excellent for marine, chemical, and heat transfer applications

- Precision Manufacturing: Strict dimensional tolerances for optimal performance

- Custom Solutions: Tailored sizes, tempers, and coatings to meet specific requirements

- Comprehensive Testing: Ensuring full compliance with ASTM B88

- Global Distribution Network: Fast and reliable worldwide delivery

11. Advantages of Choosing Womic Steel

12. Applications

Our ASTM B88 C12200 tubes are ideal for:

- Marine Industry: Seawater-cooled condensers, piping, and shipboard heat exchangers

- Power Plants: Steam condensers and cooling systems

- Desalination Plants: Corrosion-resistant piping for saltwater applications

- Chemical Processing: High-pressure, high-temperature heat exchanger tubes

- HVAC & Refrigeration: Air conditioning coils and industrial cooling systems

Conclusion

Womic Steel’s ASTM B88 C12200 Type L copper pipes offer exceptional performance, durability, and resistance to corrosion, making them a preferred choice for a wide range of piping systems. With strict adherence to ASTM standards and complete quality assurance, we ensure each delivery meets the highest expectations in functionality and reliability.

We pride ourselves on our customization services, fast production cycles, and global delivery network, ensuring your specific needs are met with precision and excellence.

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Post time: Jan-21-2026