Comparison Between 304H and 304 Stainless Steel Pipes

— Womic Steel's Manufacturing Capabilities & Product Solutions

1. Product Overview

Womic Steel is a leading manufacturer of premium-grade stainless steel pipes, offering both 304H and 304 stainless steel pipes in accordance with major international standards, including:

l ASTM A312 / A213 / A269 / A358

l ASME SA312 / SA213

l EN 10216-5 / EN 10297-2

l JIS G3459 / ISO 9329-4

l GB/T 14976 / GB/T 13296

304H and 304 are both austenitic stainless steels, but they are engineered for distinct performance environments—304H excels in high-temperature service, while 304 provides superior corrosion resistance and weldability in general-purpose applications.

2. Chemical Composition

|

Element |

304 Stainless Steel |

304H Stainless Steel |

| Carbon (C) | ≤ 0.08% | 0.04% – 0.10% |

| Chromium (Cr) | 18.0% – 20.0% | 18.0% – 20.0% |

| Nickel (Ni) | 8.0% – 11.0% | 8.0% – 11.0% |

| Manganese (Mn) | ≤ 2.00% | ≤ 2.00% |

| Silicon (Si) | ≤ 1.00% | ≤ 1.00% |

| Phosphorus (P) | ≤ 0.045% | ≤ 0.045% |

| Sulfur (S) | ≤ 0.030% | ≤ 0.030% |

| Nitrogen (N) | ≤ 0.10% | ≤ 0.10% |

| Iron (Fe) | Balance | Balance |

The higher carbon content in 304H enhances carbide precipitation (Cr₂₃C₆), improving creep resistance and high-temperature strength. 304's lower carbon content is ideal for welded structures requiring good intergranular corrosion resistance.

3. Size Range and Product Types

Womic Steel offers a wide variety of stainless steel pipes tailored for industrial, architectural, and pressure applications:

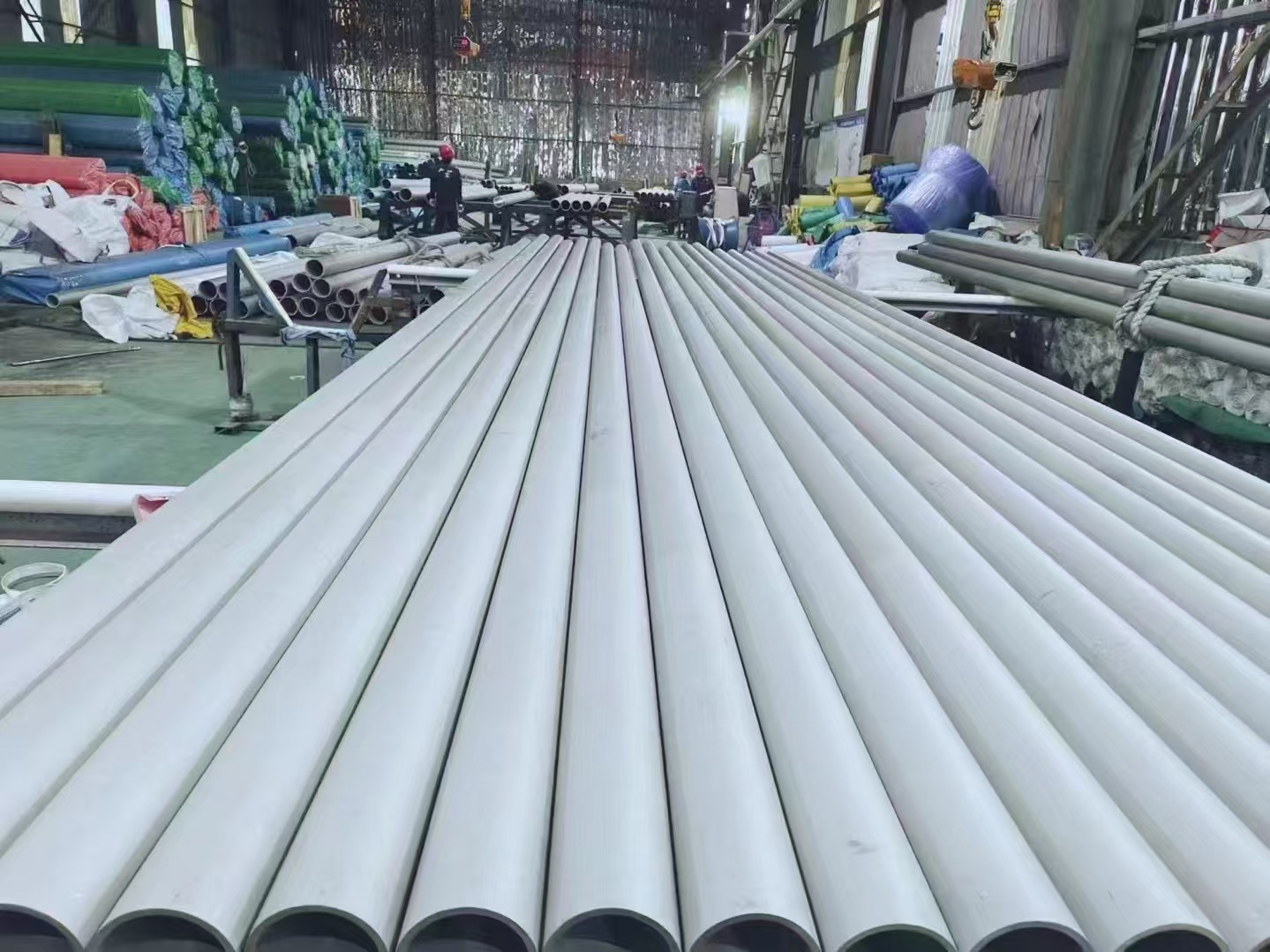

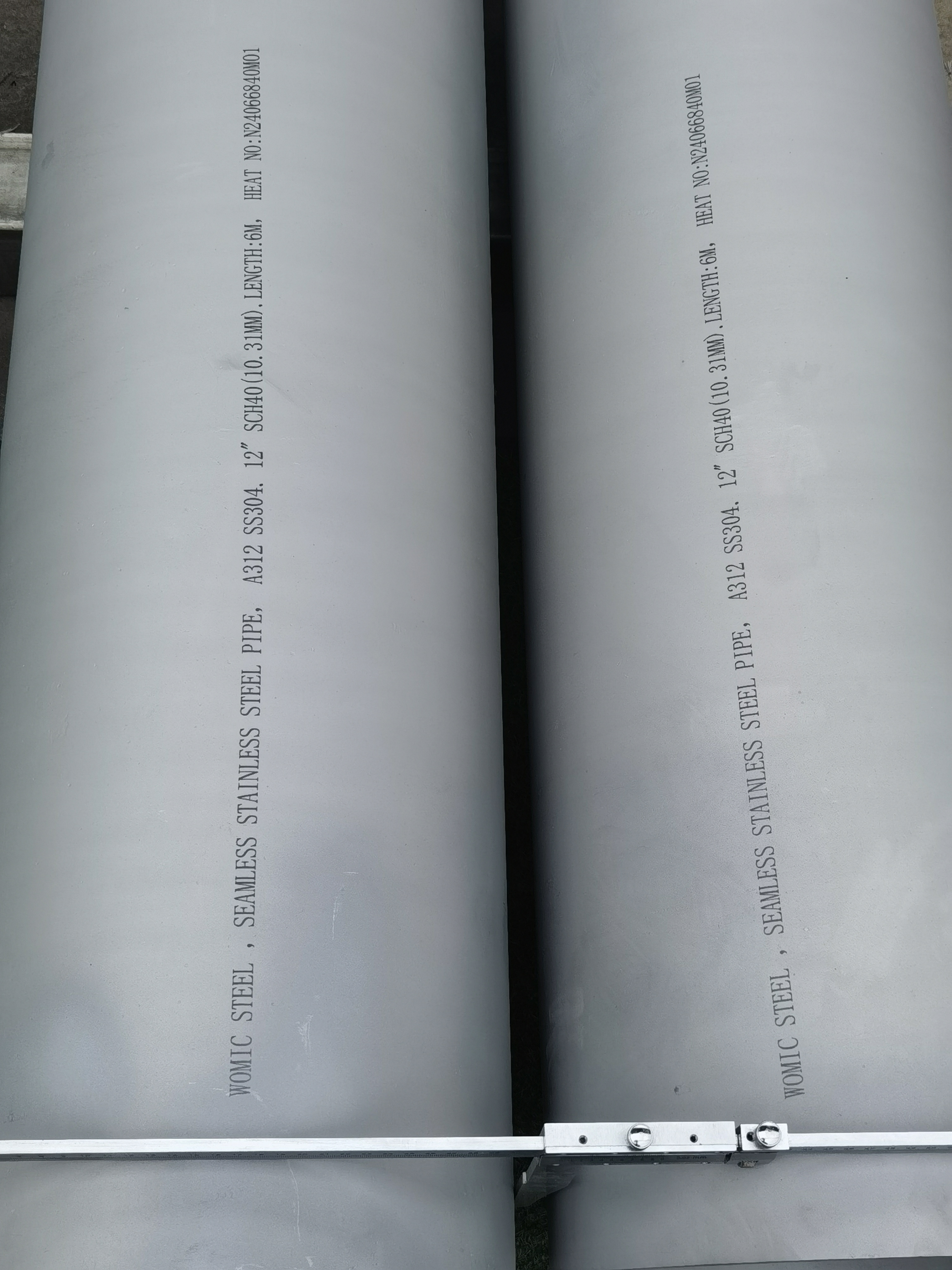

Seamless Pipes:

Outer Diameter: 6mm – 610mm

Wall Thickness: 0.5mm – 50mm

Welded Pipes (ERW / TIG / Laser):

Outer Diameter: 8mm – 1219mm

Wall Thickness: 0.5mm – 30mm

Other Options:

Heat exchanger tubes, U-bent tubes, polished tubing, and heavy-wall customized pipes.

Length: Fixed length or up to 18 meters

Surface Finishes: Pickled, annealed, polished, brushed

4. Mechanical Properties

|

Property |

304 Stainless Steel |

304H Stainless Steel |

| Tensile Strength (MPa) | ≥ 515 | ≥ 590 |

| Yield Strength 0.2% (MPa) | ≥ 205 | ≥ 235 |

| Elongation (%) | ≥ 35 | ≥ 35 |

| Hardness (HBW) | ≤ 192 | ≤ 192 |

| Creep Rupture Strength (650℃, 100,000 hrs) | ~55 MPa | ~80 MPa |

Key Insight:

304H outperforms 304 under long-term elevated temperature operation (above 550℃), making it ideal for power plant reheaters, petrochemical reformers, and thermal processing systems.

5. Heat Treatment and Welding Requirements

|

Parameter |

304 |

304H |

| Solution Annealing | 1010 – 1065℃ | ≥ 1080℃ |

| Cold Work Response | Excellent | High work hardening rate |

| Weldability | Excellent | Requires higher carbon filler metals |

| Post-Weld Heat Treatment | Optional | Recommended for critical joints |

Welding Recommendation: For 304H, Womic Steel suggests ER308H welding wire, with precise heat input control and post-weld annealing for high-reliability joints in high-pressure piping systems.

6. Corrosion Resistance Comparison

In chloride-containing environments, 304 has a higher pitting resistance.

The pitting potential of 304H is about 50mV lower, leading to earlier localized attack.

|

Test Condition |

304 |

304H |

| Cl⁻ Concentration 180ppm, 2 years | No leakage | Perforation observed |

| Annual Corrosion Rate (mm/year) | ~0.015 mm/year | ~0.020 mm/year |

Use 304 in environments requiring excellent general and localized corrosion resistance such as marine cooling systems, food processing, or chemical tanks.

7. Testing and Quality Certification

Womic Steel performs comprehensive quality inspections and adheres to strict QA/QC procedures:

l Chemical Analysis: Optical Emission Spectrometer (OES), ICP-MS

l Mechanical Testing: Tensile, hardness (HBW), impact (Charpy V-notch)

l Non-Destructive Testing (NDT): Eddy current, ultrasonic, radiographic, liquid penetrant

l Corrosion Testing: ASTM A262 IGC, Salt Spray, Pitting Test

All pipes can be provided with:

EN 10204 3.1 / 3.2 Certification

ISO 9001, PED, SGS, TUV, BV Approvals

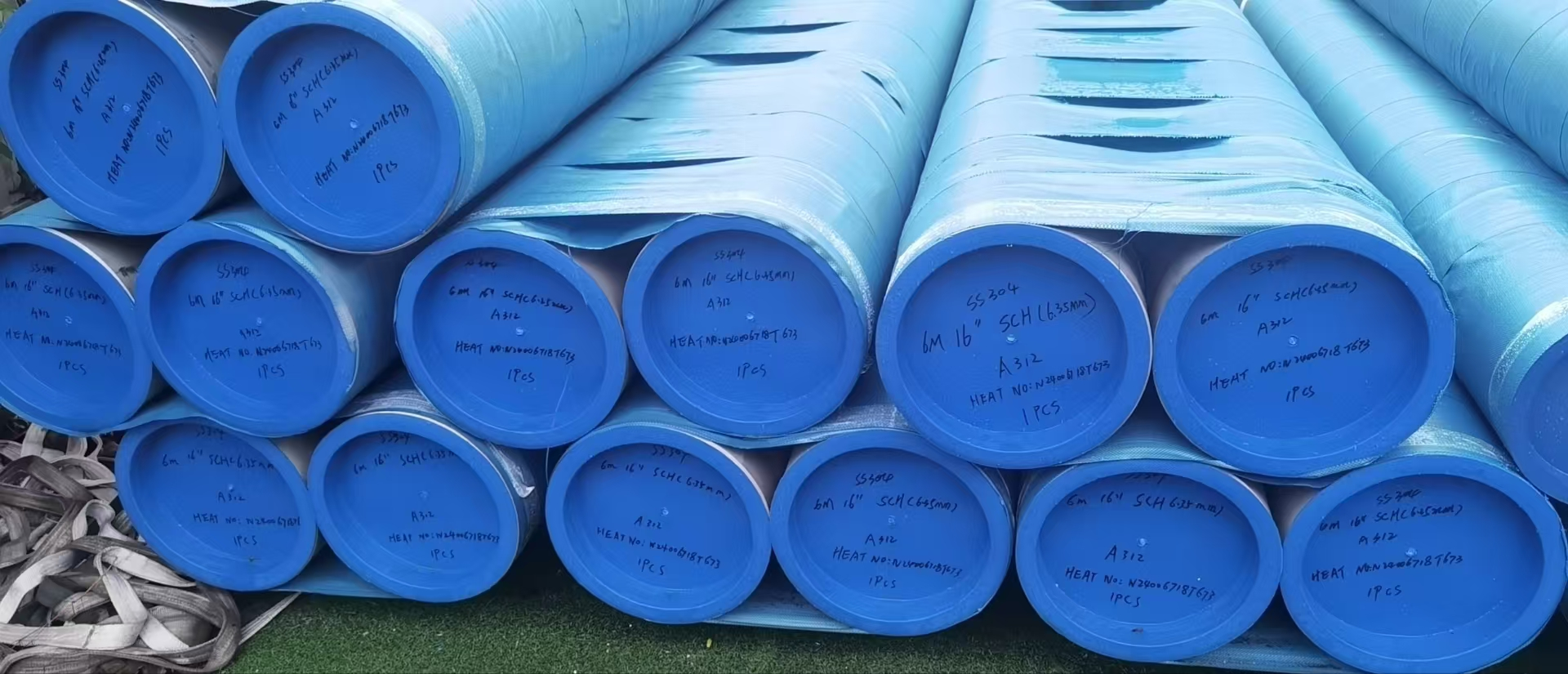

8. Packaging and Transport Advantages

Standard Packaging:

Hexagonal bundles with end caps, plastic wrapping, waterproof cloth, wooden boxes, or steel racks.

Markings:

Each pipe is laser-engraved with heat number, material grade, size, and Womic Steel branding. Custom logo or QR traceability optional.

Logistics:

Womic Steel cooperates directly with shipping lines and freight forwarders. Strong advantages on Asia–South America, Middle East, and Southeast Asia routes. Fast FOB/CIF/DDP delivery options.

9. Surface Treatment and Processing Services

l Cutting, slotting, bending, beveling

l Polishing (Ra < 0.4μm for food-grade use)

l Matching Components: Elbows, tees, flanges, valves

Womic Steel also offers pre-fabrication services for modular pipeline assemblies.

10. Production Capacity and Lead Time

Annual Production: 30,000+ tons

Production Lines:

24 Cold Draw Benches

10 Automatic Welding Lines

3 Bright Annealing Furnaces

Raw Material Stock:

Over 1,200 tons of 304 / 304H coils and billets

Delivery Time:

15 – 25 working days for standard orders; expedited delivery available in 7 days for urgent projects.

11. Application Scenarios and Material Selection Guide

|

Application Area |

Recommended Grade |

Justification |

| Kitchen equipment, medical instruments, curtain wall structures | 304 | Excellent corrosion resistance and formability |

| Petrochemical furnace tubes, heat treatment rollers, power boiler reheaters | 304H | Superior high-temperature strength and creep resistance |

12. Why Choose Womic Steel?

l Stable Raw Material Supply: Strategic partnerships with Baosteel, TISCO, Zhangpu ensure material continuity

l Advanced Technology: In-house annealing, online NDT, automated dimensional control

l Flexible Customization: Large OD, thick wall, shaped pipes, and low MOQ accepted

l Global Project Experience: Supplied to Codelco Chile, Total, Qatar Energy, Malaysian Petrochem, and more

l For further technical specifications, pricing, or project consultation, please contact Womic Steel’s International Sales Team — your trusted stainless steel partner.

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Post time: Apr-18-2025