High-Quality Manufacturing, Global Standards Compliance, and Comprehensive Customization Services

Womic Steel proudly stands as a leading manufacturer of stainless steel pipe fittings, offering a complete range of products engineered to meet international quality benchmarks. With advanced manufacturing facilities, an expert technical team, and efficient raw material sourcing, Womic Steel ensures timely delivery and reliable performance for all your piping system needs.

Material Grades & International Standards

Womic Steel manufactures stainless steel pipe fittings using high-grade materials such as 304, 304L, 304H, 316, 316L, 321, 317L, 310S, and 904L, among others. These fittings comply with a wide range of international standards, including:

1. ASME/ANSI B16.9, B16.11, B16.5

2. ASTM A403, A182, A312

3. EN 10253-3/EN 10253-4

4. DIN 2605, DIN 2615, DIN 2616, DIN 2617

5. ISO, JIS, and GOST standards as per project or drawing requirements

Common Types of Stainless Steel Pipe Fittings

Womic Steel supplies a complete series of stainless steel pipe fittings that include:

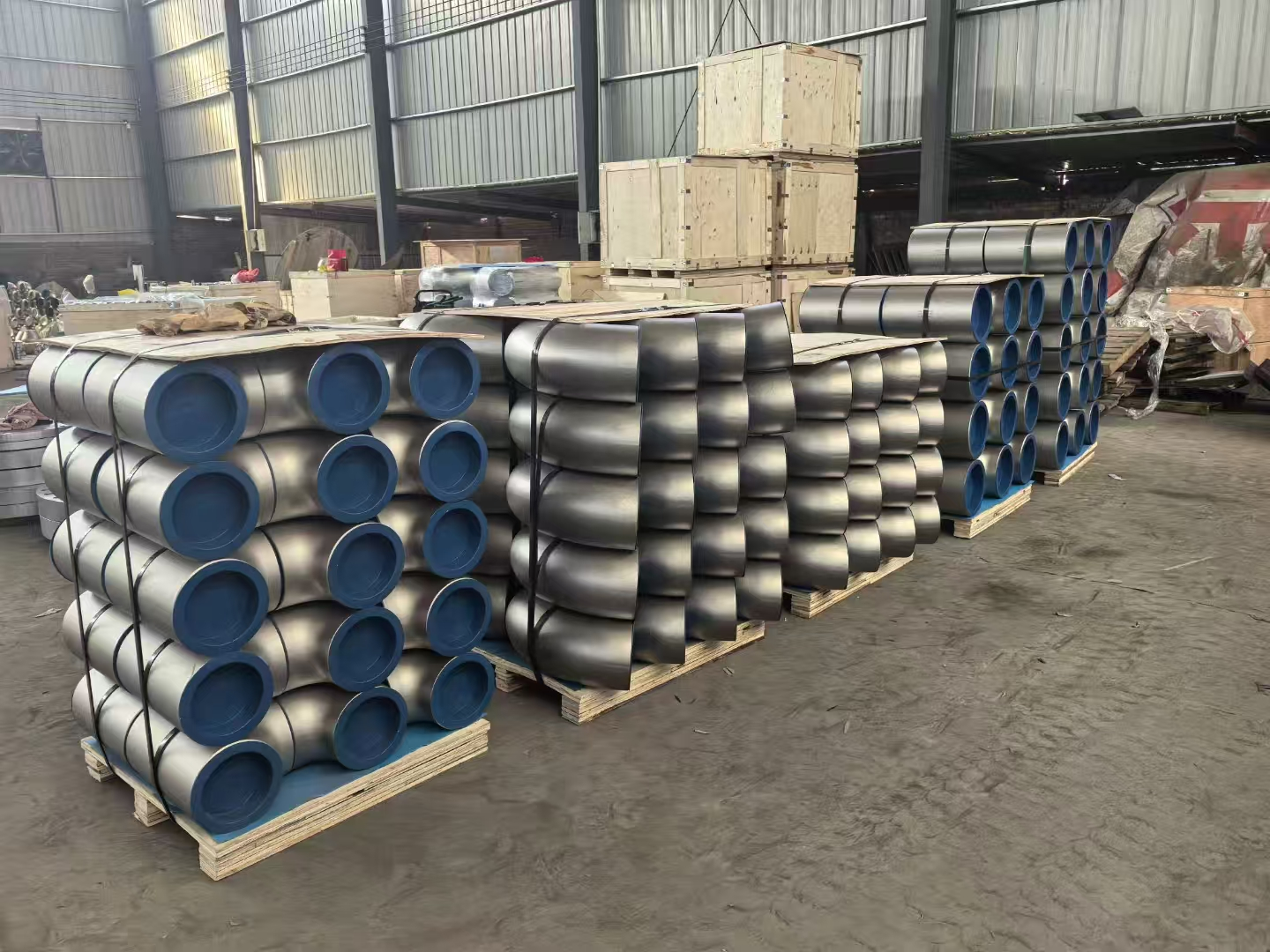

1. Elbows (45°, 90°, 180°)

2. Tees – Equal and reducing

3. Reducers – Concentric and eccentric

4. Caps and End Covers

5. Stub Ends

6. Couplings, Unions, Nipples, Bushings

7. Flanges – Weld neck, slip-on, threaded, socket weld, blind, lap joint

Specifications and Size Range

Womic Steel offers stainless steel pipe fittings in the following size ranges:

- Seamless fittings: ½” – 24” (DN15 – DN600)

- Welded fittings: up to 72” (DN1800)

- Wall Thickness: SCH 10S to SCH XXS, or customized

- Custom angles and dimensions available upon request

Chemical Composition & Mechanical Properties

Typical Chemical Composition (304L):

- C ≤ 0.035%

- Cr: 18.0 – 20.0%

- Ni: 8.0 – 12.0%

- Mn ≤ 2.0%, Si ≤ 1.0%, P ≤ 0.045%, S ≤ 0.03%

Mechanical Properties (ASTM A403 WP304L):

- Tensile Strength ≥ 485 MPa

- Yield Strength ≥ 170 MPa

- Elongation ≥ 30%

- Hardness: ≤ 90 HRB

Optional Impact Test:

- Impact tests at -46°C (Charpy V-notch) available upon request

Manufacturing Process & Heat Treatment

The stainless steel pipe fittings are manufactured using hot forming, cold forming, or machining. The process includes cutting, forging, heat treatment (solution annealing), pickling, passivation, and precision machining. All fittings undergo solution annealing with water or air quenching.

Testing and Inspection

Each fitting undergoes strict quality control, including:

- Visual & Dimensional Inspection

- Hydrostatic Pressure Test

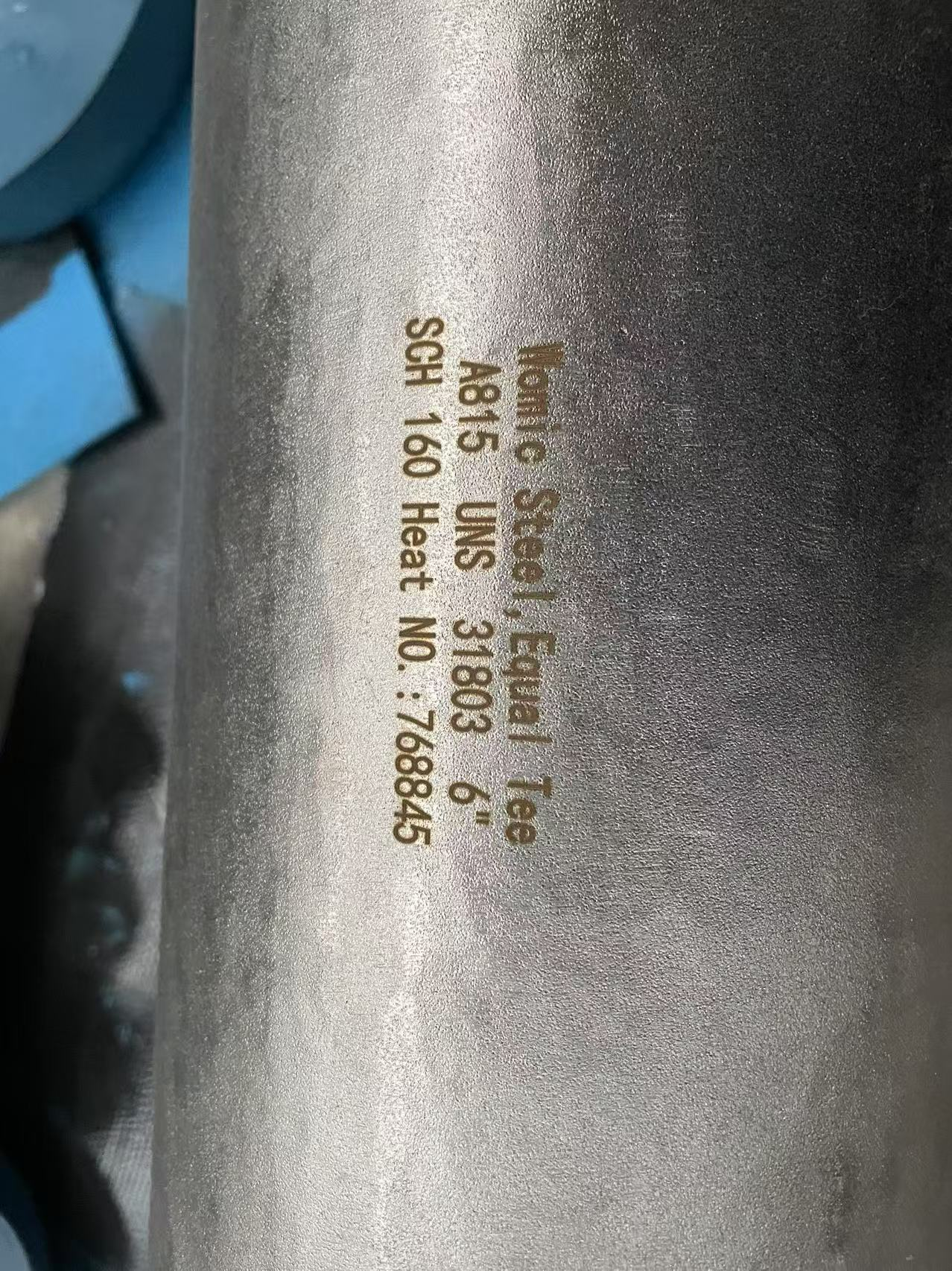

- PMI (Positive Material Identification)

- Ultrasonic Testing (UT)

- Dye Penetrant Test (PT)

- Radiographic Testing (RT)

- Hardness Testing (HBW)

Certifications

Womic Steel is certified by:

- ISO 9001:2015

- PED 2014/68/EU (for CE marking)

- AD 2000-W0

- EN 10204 3.1 / 3.2 material certificates

Applications

Stainless steel pipe fittings are widely used in:

1. Oil & Gas

2. Petrochemical

3. Food & Beverage

4. Pharmaceutical

5. Marine & Shipbuilding

6. Water Treatment

7. Power Generation

8. HVAC and Fire Fighting Systems

Production Lead Time and Packaging

Typical lead time:

- Stock: 3–5 days

- Standard: 2–4 weeks

- Custom: 4–6 weeks

Packaging:

- Export plywood cases or steel frames

- Plastic caps and film protection

- Markings: Heat No., Grade, Size, Standard, Logo

Transportation Advantages and Processing Services

Womic Steel offers fast shipping, flexible INCOTERMS, and container consolidation. Processing services include precision cutting, welding, beveling, threading, pickling, and passivation.

Anti-corrosion protection includes neutral oil, PE bags, or shrink wrapping. Note: Epoxy, FBE, or 3LPE coatings are not applied to stainless steel pipe fittings.

Our Advantages

1. In-house capacity over 10,000 tons/year

2. Skilled R&D and QC teams

3. Fast raw material sourcing

4. Full customization services

5. 100% inspection with traceability

6. Fast response and delivery

For inquiries, drawings, or specifications, please contact Womic Steel today. Womic Steel – Your Trusted Partner for Stainless Steel Pipe Fittings Worldwide.

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Post time: Apr-19-2025