Womic Copper is proud to offer premium-quality copper tube solutions based on T2 and T3 grades, manufactured under the national standard GB/T 5231-2012. Our copper tubes are engineered for high precision, excellent electrical and thermal conductivity, and reliable corrosion resistance — serving critical roles across power systems, new energy, electronics, aerospace, and precision engineering industries.

1. Material Composition & Performance

T2 Copper Tube (Equivalent to ASTM C11000):

- Purity: ≥ 99.90% Cu

- Electrical Conductivity: ≥ 58 MS/m (IACS 100%)

- Thermal Conductivity: ≥ 390 W/(m·K)

- Hardness: HBW 40-75 depending on temper

- Magnetic Permeability: ≤ 1.003 (non-magnetic)

T3 Copper Tube:

- Purity: ≥ 99.70% Cu

- Electrical Conductivity: ≥ 50 MS/m

- Cost Efficiency: ~5% lower than T2

- Good Processability: Suitable for bending, stamping, and surface treatment

2. Production Process

Womic Copper uses state-of-the-art equipment and refined production techniques to ensure consistent quality:

1. Raw Material Selection

2. Melting & Casting

3. Extrusion & Drawing

4. Annealing

5. Surface Finishing

6. Inspection

3. Application Scenarios

T2 Copper Tube:

- Electric Power: Transformer windings, high-voltage busbars

- New Energy: Battery module connectors, CTP cell interconnects

- Precision Engineering: Semiconductor equipment grounding, aerospace landing gear sleeves

- Medical: CT machine rotating connectors (FDA biocompatibility certified)

T3 Copper Tube:

- Automotive: Spark plug electrodes, fuel system components

- Construction: Residential electrical wiring, decorative pipework

- HVAC: Air conditioner compressors, heat exchanger tubing

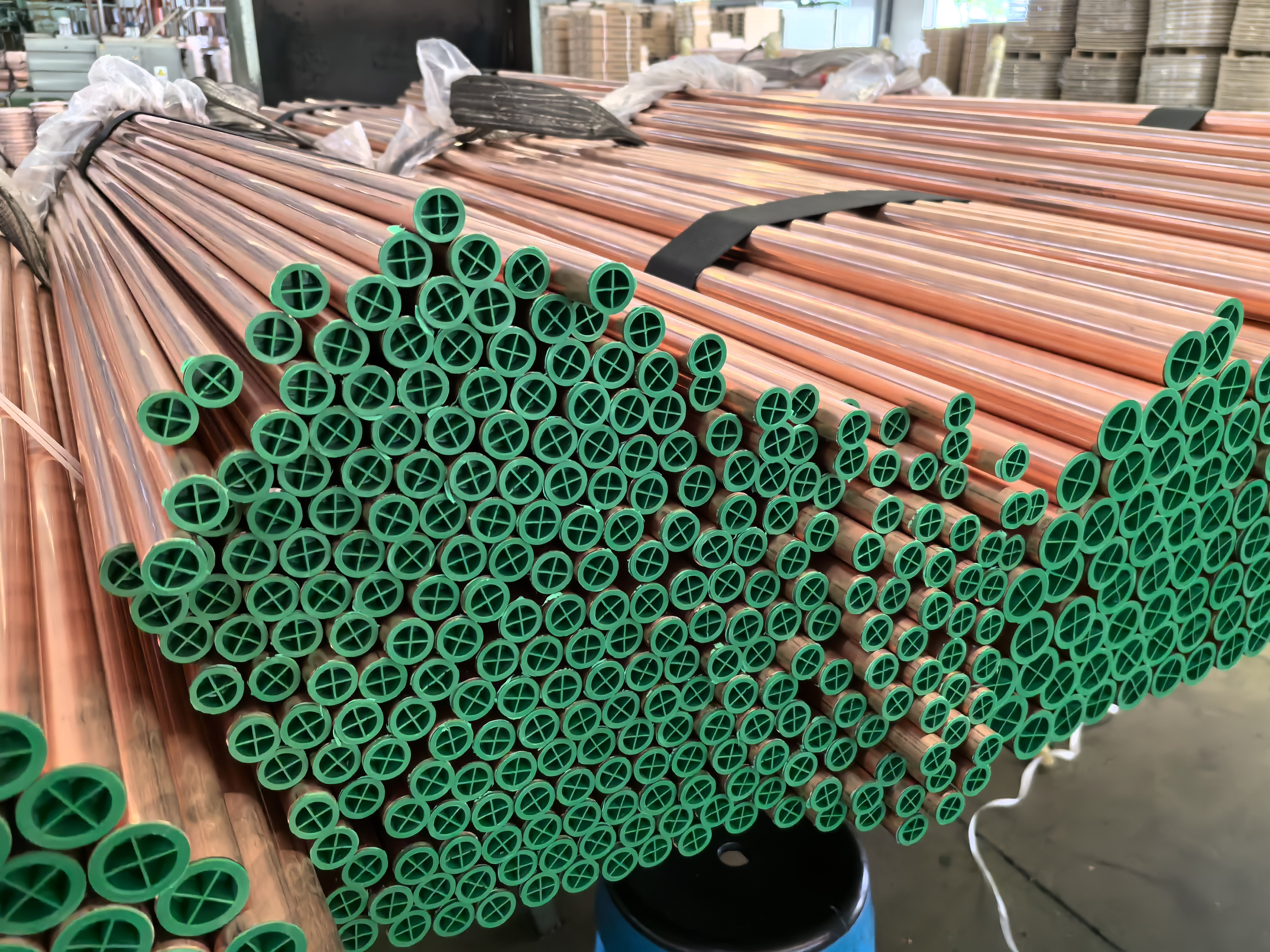

4. Packaging Requirements

To ensure the integrity and cleanliness of copper tubes during transportation and storage:

- Inner Packing: Each tube is capped and sealed with corrosion-resistant PE film

- Outer Packing: Bundled with waterproof kraft paper and anti-collision foam, fixed in wooden crates

- Labeling: Each bundle marked with grade, lot number, dimensions, and heat number

5. Transportation Modes

Womic Copper provides flexible and secure delivery solutions:

- Domestic Delivery: Truck + rail transport for major project sites

- International Export: Sea freight via Tianjin and Shanghai ports

- Container Load Options:

• 20GP: Suitable for < 25MT of small-diameter coils

• 40HQ: For bulk order of long straight tubes

- Securing Methods: Steel straps, anti-slip mats, and container bracing to prevent damage in transit

6. Production Advantages of Womic Copper- Fully Integrated Supply Chain: From copper ingot casting to finished tube extrusion

- Precision Engineering: CNC-controlled rolling and cutting systems

- High Conductivity Guarantee: 100% IACS for T2 tubes, certified by third-party labs

- Global Compliance: Products meet GB/T 5231-2012, ASTM B75, and IEC 60228 standards

- Flexible Customization: Supports non-standard sizes, alloy modifications, and complex geometries

- Innovation-Driven: Adoption of pulse electroplating, composite drawing technology, and eco-friendly annealing

7. Industry Trends & Emerging Applications

- Electric Vehicles: T2 busbars used in 800V platforms, now require silver-plating to reduce contact resistance

- Sustainability: Pulse plating reduces energy usage by 30%, improves coating uniformity by 50%

- Aerospace & Defense: Ultra-fine T2 wires used in high-frequency RF shielding at 10GHz

- Smart Buildings: T3 decorative tubes now support anti-oxidation coatings for enhanced outdoor durability

For all your copper tube requirements, Womic Copper provides quality, reliability, and innovation — engineered to power tomorrow’s technologies. Reach out to our technical sales team for samples, datasheets, or custom specifications.

Choose Womic Steel Group as your reliable partner for copper tubes and unbeatable delivery performance. Welcome Inquiry!

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Post time: Apr-21-2025