1. Product Overview

The steel ladle manufactured in accordance with ASTM A27 Grade 70-36 is a heavy-duty carbon steel casting designed for handling, transportation, and temporary containment of molten slag or hot materials in metallurgical and industrial applications.

This grade is specifically selected to provide an optimal balance between strength, ductility, and resistance to thermal and mechanical stress, making it particularly suitable for ladles subjected to repeated lifting operations, thermal cycling, and impact loading.

2. Applicable Standard

ASTM A27 / A27M – Steel Castings, Carbon, for General Application

Material Grade: ASTM A27 Grade 70-36

All castings shall be produced, tested, and inspected in full compliance with the requirements of ASTM A27 unless otherwise specified by the purchaser.

3. Material Characteristics – ASTM A27 Grade 70-36

ASTM A27 Grade 70-36 is a medium-strength carbon steel casting grade characterized by good plasticity and structural reliability.

3.1 Mechanical Properties (Minimum)

|

Property |

Requirement |

| Tensile Strength | ≥ 70,000 psi (≈ 485 MPa) |

| Yield Strength | ≥ 36,000 psi (≈ 250 MPa) |

| Elongation (in 2 in / 50 mm) | ≥ 22% |

| Reduction of Area | ≥ 30% |

These mechanical properties ensure sufficient load-bearing capacity while maintaining excellent resistance to cracking and brittle fracture.

3.2 Chemical Composition (Typical Limits)

|

Element |

Max. Content |

| Carbon (C) | ≤ 0.35% |

| Manganese (Mn) | ≤ 0.70% |

| Phosphorus (P) | ≤ 0.05% |

| Sulfur (S) | ≤ 0.06% |

The controlled carbon and manganese content contributes to stable casting quality and reliable mechanical performance without the need for alloying elements.

4. Design and Structural Features of the Ladle

l One-piece cast body or cast body with integrally cast lifting hooks / lifting lugs

l Smooth internal geometry to minimize stress concentration

l Adequate wall thickness designed to withstand thermal gradients and mechanical handling loads

l Lifting points designed based on full-load lifting conditions, including safety factors

The ladle design emphasizes structural integrity and service durability, especially under high-temperature exposure and repeated crane handling.

5. Manufacturing Process

5.1 Casting Method

l Sand casting using controlled molding materials suitable for large-section steel castings

l Single heat casting is recommended to ensure chemical consistency

5.2 Melting and Pouring

l Electric arc furnace (EAF) or induction furnace

l Strict control of chemical composition prior to pouring

l Controlled pouring temperature to minimize internal defects

5.3 Heat Treatment

Normalizing heat treatment is typically applied

Purpose:

l Refine grain structure

l Improve toughness and uniform mechanical properties

l Relieve internal casting stresses

Heat treatment parameters shall be documented and traceable.

6. Quality Control and Inspection

6.1 Chemical Analysis

l Heat analysis conducted for each melt

l Results recorded in the Mill Test Certificate (MTC)

6.2 Mechanical Testing

l Test coupons cast from the same heat and heat-treated together with the ladle:

l Tensile test

l Yield strength verification

l Elongation and reduction of area

6.3 Non-Destructive Examination (as applicable)

Depending on project requirements:

l Visual inspection (100%)

l Magnetic Particle Testing (MT) for surface cracks

l Ultrasonic Testing (UT) for internal soundness

6.4 Dimensional Inspection

l Verification against approved drawings

l Special attention to lifting hook geometry and critical load-bearing sections

7. Documentation and Certification

The following documents are typically provided:

l Mill Test Certificate (EN 10204 3.1 or equivalent)

l Chemical composition report

l Mechanical test results

l Heat treatment record

l NDT reports (if required)

l Dimensional inspection report

All documentation is traceable to the corresponding heat and casting batch.

8. Application Scope

Steel ladles produced to ASTM A27 Grade 70-36 are widely used in:

l Steel plants and foundries

l Slag handling systems

l Metallurgical workshops

l Heavy industrial material transfer operations

This grade is especially suitable for applications where ductility and safety under dynamic load are critical.

9. Advantages of Using ASTM A27 Grade 70-36 for Ladles

l Excellent balance between strength and ductility

l Reduced risk of brittle fracture under thermal shock

l Cost-effective compared with higher-strength, lower-ductility grades

l Proven reliability for heavy casting applications

l Wide acceptance by inspectors and engineering companies

Packaging & Transport Information

Suggested NCM (Tariff Code): 8454100000

Type of Packaging Used:

Custom-built wooden skid or crate for sea transport.

Anti-rust oil or vapor corrosion inhibitor film applied to surfaces.

Secure lashing with steel bands and wood blocking to avoid movement during transit.

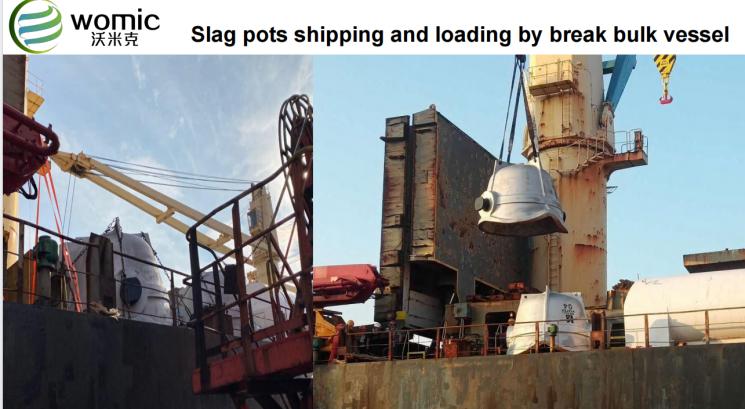

Type of shipping methods: Container, bulk vessel:

Flat Rack Container – Preferred for ease of crane loading/unloading.

Open Top Container – Used when vertical clearance is a concern.

Bulk Vessel - For the big size can not loaded into containers

Need a License for Local Transport?

Yes, due to the oversized nature of the pots, a special transport license is typically required for road or rail delivery. Documentation and technical drawings can be provided to assist with permit applications.

In Case of Special Oversized Cargo, What Type of Equipment Shall Be Used for Handling?

Crawler Cranes with sufficient capacity for small sized and weight.

Shore cranes for over weight slag pots with weight over 28tons

All lifting points are engineered and tested to ensure safe and compliant handling.

10. Conclusion

ASTM A27 Grade 70-36 is a technically sound and economically efficient material choice for steel ladles used in demanding industrial environments. Its mechanical properties, combined with controlled chemistry and proper heat treatment, provide long-term operational reliability and safety.

We pride ourselves on our customization services, fast production cycles, and global delivery network, ensuring your specific needs are met with precision and excellence.

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Post time: Jan-22-2026