1. Company Overview

Womic Steel is a globally recognized manufacturer of stainless steel pipes and tubes, specializing in high-grade materials for critical applications. With decades of experience and a state-of-the-art production facility, we have positioned ourselves as a reliable partner for industries that demand precision, durability, and absolute quality assurance. Our SA213-TP304L seamless tubes are engineered for high-performance environments, offering unparalleled corrosion resistance, mechanical strength, and process integrity.

2. Applicable Standards

Our SA213-TP304L tubes are manufactured in full compliance with ASTM A213/A213M, which specifies seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes. Furthermore, our products meet the requirements of ASME Section II for pressure vessels and are certified according to ISO 9001:2015 and PED 2014/68/EU. Third-party inspections such as TUV, SGS, Lloyd’s Register, and DNV can be arranged to support project-specific documentation and quality control.

3. Dimensions and Product Range

Womic Steel offers SA213-TP304L tubes in a wide range of sizes to cater to both standard and customized applications:

- Outer Diameter: 6mm to 273.1mm (1/4" to 10")

- Wall Thickness: 0.5mm to 12mm

- Length: Up to 12 meters or tailored to exact client specifications

We also offer tight dimensional tolerances with OD deviation up to ±0.05mm and wall thickness precision up to ±0.03mm. Our production line supports metric and imperial sizing, with custom cutting, bending, and beveling services.

4. Chemical and Mechanical Properties

SA213-TP304L is a low-carbon variation of 304 stainless steel that ensures superior weldability and minimizes the risk of intergranular corrosion after welding. Its composition is finely tuned for reliability in high-temperature and corrosive environments:

Typical Chemical Composition:

- Carbon (C): ≤ 0.035%

- Chromium (Cr): 18.0–20.0%

- Nickel (Ni): 8.0–12.0%

- Manganese (Mn): ≤ 2.00%

- Silicon (Si): ≤ 1.00%

- Phosphorus (P): ≤ 0.045%

- Sulfur (S): ≤ 0.030%

Mechanical Strength:

- Tensile Strength: ≥ 485 MPa

- Yield Strength: ≥ 170 MPa

- Elongation: ≥ 35%

- Hardness: ≤ 90 HRB

This combination ensures exceptional performance in pressure-bearing systems, aggressive chemical environments, and high thermal cycling applications.

5. Advanced Manufacturing Process

Womic Steel’s SA213-TP304L tubes are crafted using a sequence of precisely controlled manufacturing steps:

1. Raw Material Selection: We procure billets from premium domestic suppliers with stable elemental consistency. All raw materials are verified using Positive Material Identification (PMI) technology.

2. Hot Piercing: High-temperature extrusion creates the hollow profile, ensuring uniform grain structure and optimal concentricity.

3. Cold Drawing: This step enhances mechanical properties, reduces surface roughness, and brings tubes to their final dimensions.

4. Solution Annealing: Conducted at 1050–1150°C followed by rapid water quenching, this step relieves internal stress and improves corrosion resistance.

5. Pickling and Passivation: The tube surfaces are acid-treated and chemically passivated to restore a protective oxide layer.

6. Straightening & Sizing: Tubes are passed through multi-roll machines for dimensional perfection and calibrated according to order requirements.

6. Rigorous Testing Protocols

To guarantee consistent quality, Womic Steel enforces comprehensive in-house and third-party testing:

Hydrostatic Testing: Confirms the integrity of each tube under high-pressure conditions.

Eddy Current Testing: Detects microcracks and discontinuities without damaging the tube.

Ultrasonic Inspection: Checks internal structure uniformity and detects hidden flaws.

Intergranular Corrosion Testing (IGC): Validates post-weld corrosion resistance.

Tensile and Hardness Testing: Mechanical properties are tested per ASTM A370 to ensure full compliance.

Surface Finish Inspection: Confirms compliance with Ra ≤ 1.6μm (or better, based on requirement).

7. Certifications and Quality Assurance

Each product batch is delivered with a full Mill Test Certificate (MTC) per EN 10204 3.1 or 3.2. Womic Steel’s plant is certified to ISO 9001:2015, and we are approved suppliers for many international EPC firms. All pressure-related products are certified under the ASME Boiler and Pressure Vessel Code and the European Pressure Equipment Directive (PED).

8. Application Industries

The SA213-TP304L tube is widely used in:

Power Generation: Superheaters, reheaters, and condensers

Chemical and Petrochemical Plants: Process lines and pressure vessels

Pharmaceutical: Clean steam and WFI (Water for Injection) systems

Food and Beverage: Hygienic fluid transport

Marine Engineering: Heat exchangers and seawater cooling lines

Oil & Gas: Downstream gas transmission and flare lines

Its corrosion resistance and ability to withstand cyclic thermal stress make it indispensable in extreme environments.

9. Production Cycle and Delivery Lead Time

Womic Steel offers industry-leading delivery timelines backed by streamlined supply chains and large-scale production:

- Standard Production Lead Time: 15–25 working days

- Expedited Delivery for Urgent Orders: As fast as 10 working days

- Monthly Production Capacity: Over 1200 metric tons

- Raw Material Inventory: Over 500 tons ready-to-draw billets in stock

This ensures flexibility and reliability, even under tight project schedules.

10. Packaging and Traceability

Our packaging ensures total protection and traceability during transit and storage:

- Plastic end caps prevent contamination

- Bundled and wrapped in anti-rust film and woven belts

- Seaworthy wooden crates or pallets for containerized shipping

- Each bundle marked with heat number, size, material, batch ID, and QR code

This allows clients to track every tube back to its production heat for complete transparency.

11. Transportation and Logistics Strength

Womic Steel operates from major Chinese ports, offering smooth global logistics:

- FCL and LCL shipments with container optimization

- Steel strapping and wooden wedges to secure cargo

- Partnerships with top freight forwarders for timely deliveries

- Customs clearance support and pre-shipment inspection coordination

Clients benefit from real-time shipping updates and accurate ETAs.

12. In-House Processing and Fabrication

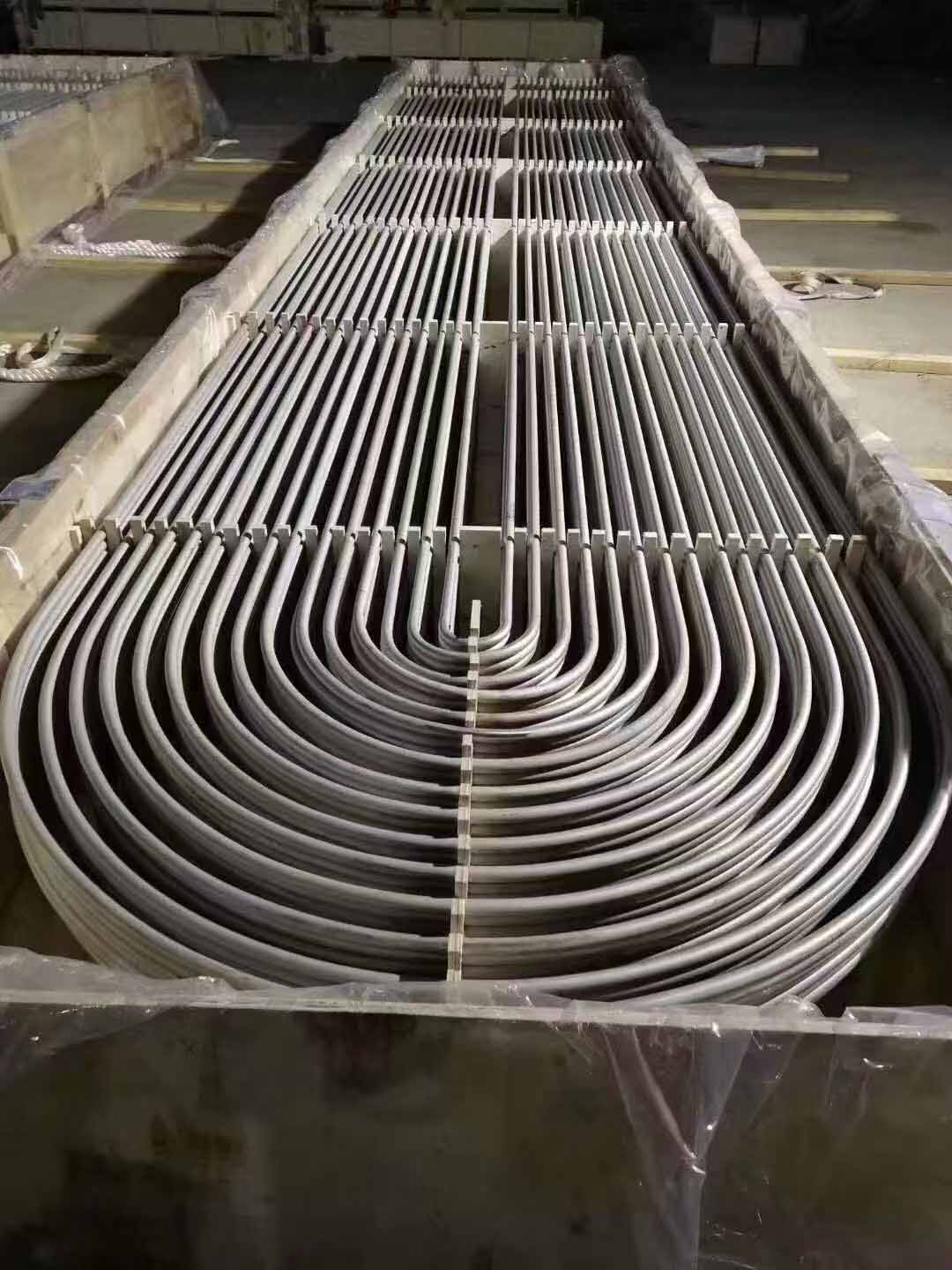

We go beyond tube manufacturing by offering tailored processing services:

- U-bending and serpentine coil formation

- End beveling, threading, and facing

- Slotting and perforation for filter tubes

- Surface polishing (Ra ≤ 0.4μm for sanitary uses)

These value-added services eliminate the need for secondary vendors, saving clients time and cost.

13. Why Choose Womic Steel?

Womic Steel provides a full-spectrum stainless solution with unmatched advantages:

- Rapid raw material availability through long-term mill partnerships

- Automated lines for drawing, annealing, and inspection

- Technical engineers with over 20 years of field experience

- Responsive customer service and multilingual support

- On-site quality control and 100% traceability

From prototype to large-volume production, we ensure top-tier reliability, consistency, and customer satisfaction.

Choose Womic Steel Group as your reliable partner for Stainless Steel tubes and unbeatable delivery performance. Welcome Inquiry!

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Post time: Apr-21-2025