1. Material Overview

347H stainless steel pipe is a high-carbon niobium-stabilized austenitic stainless steel known for its superior high-temperature strength, excellent weldability, and outstanding resistance to intergranular corrosion. The addition of niobium (Nb) improves creep strength and prevents chromium carbide precipitation along grain boundaries, ensuring enhanced resistance to sensitization.

2. Chemical Composition (Typical)

|

Element |

Content (%) |

|

C |

0.04 – 0.10 |

|

Cr |

17.0 – 19.0 |

|

Ni |

9.0 – 13.0 |

|

Si |

≤ 1.0 |

|

Mn |

≤ 2.00 |

|

P |

≤ 0.045 |

|

S |

≤ 0.030 |

3. Mechanical & Corrosion Properties

Mechanical Properties (ASTM A213):

- Tensile Strength ≥ 515 MPa

- Yield Strength ≥ 205 MPa

- Elongation ≥ 35%

- Creep rupture strength at 600°C: >100 MPa

Corrosion Resistance:

- Excellent intergranular corrosion resistance due to Nb stabilization

- Good resistance in nitric acid, acetic acid, alkaline environments, and seawater

- Tested for molten salt corrosion, proven performance in CSP molten salt storage tanks

- Slightly more sensitive to chloride-induced pitting than 316L, mitigated by passivation and surface treatment

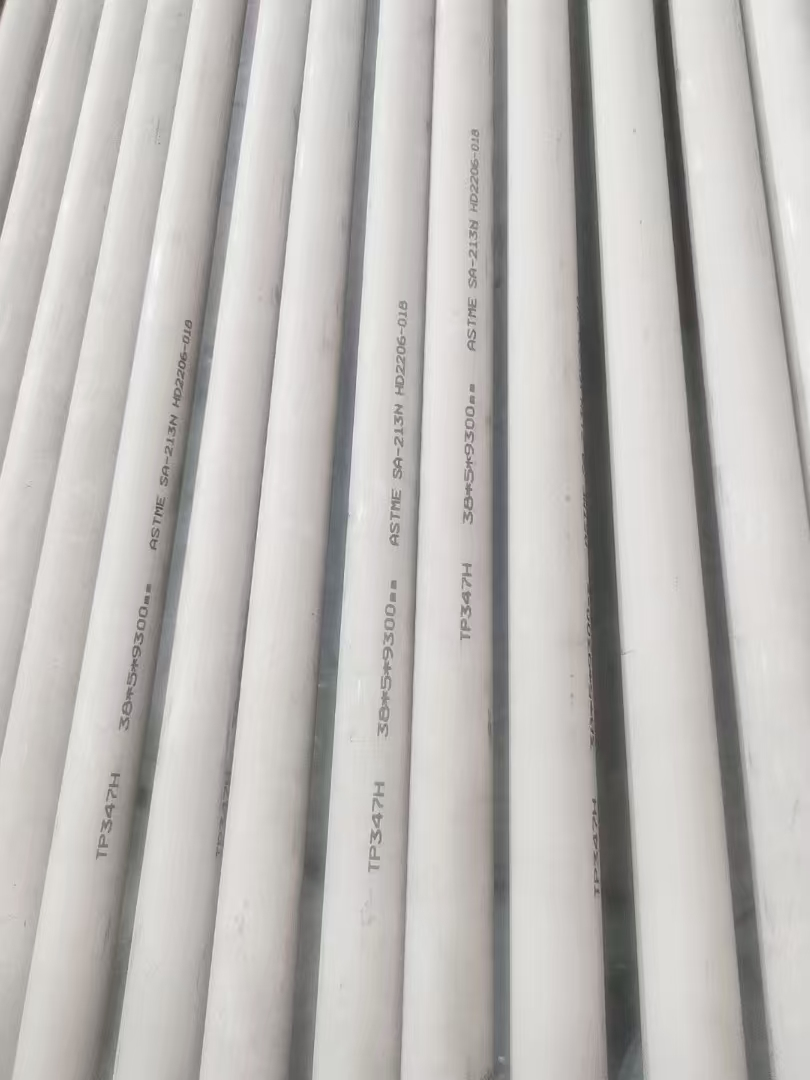

4. Common Product Specifications

Dimensions:

- Seamless Pipe: OD 1/4”–36”, wall thickness SCH10–SCH160

- Precision Tubes: OD 10mm–108mm, cold drawn

- Welded Pipe: Thin to thick wall pipes using TIG, PAW, and SAW welding

- Length: Up to 12 meters; custom cut lengths available

Manufacturing Standards:

- ASTM A213/A312, ASME SA213/SA312

- EN 10216-5, GB/T 5310

- Pressure vessel compliant: PED, AD2000 W0, ASME Code Section VIII Div. 1

5. Manufacturing Process

1. Raw Material: Certified steel billets from domestic and global mills

2. Hot Rolling: Billets heated to 1150–1200°C, pierced and rolled for large-diameter or thick-wall tubes

3. Cold Drawing: Multiple-pass cold drawing for precision size and surface finish

4. Heat Treatment: Solution annealing at 980–1150°C, rapid water quenching to suppress carbide precipitation

5. Welding: GTAW (TIG), PAW, and SAW processes, using ER347 filler wire for stabilization; back purging options available

6. Surface Finish: Pickling, passivation (HNO₃/HF), and mechanical polishing (Ra ≤ 0.2µm upon request)

7. Inspection: 100% RT (radiographic testing) for welds; ultrasonic, hydrostatic, PMI, intergranular corrosion testing as required

6. Certification & Quality Control

Womic Steel's 347H stainless steel pipes are certified under:

- ISO 9001:2015

- PED 2014/68/EU

- AD2000 W0

- ASME Boiler & Pressure Vessel Code

Each batch undergoes rigorous testing, including:

- Mechanical tests (tensile, impact, flattening, flaring)

- Corrosion tests (IGC per ASTM A262)

- Non-destructive testing (UT, RT, Eddy current)

- Dimensional inspection and full traceability

7. Application Fields

347H stainless steel pipe is widely used in:

- Power Generation: Superheaters, reheaters, main steam pipelines in subcritical and supercritical thermal power plants

- Solar Thermal Energy: Molten salt heat storage tanks (450–565°C), proven use in projects across China (Yumen, Haixi)

- Petrochemical: Furnace tubes, hydroprocessing reactors (resistant to H₂-H₂S-H₂O environments)

- Aerospace: Engine exhaust ducts and turbine air supply pipes (operating up to 850°C)

- Heat Exchangers: High-temperature condensers and piping in refineries and marine systems

8. Production Lead Time

- Seamless Tubes (Standard Sizes): 15–25 days

- Custom Dimensions/Thick Wall Pipes: 30–45 days

- Large-Scale Orders: Capacity of over 3,000 tons/month ensures rapid delivery even under urgent timelines

9. Packaging & Logistics

Womic Steel offers secure and customizable packaging:

- Seaworthy Wooden Cases or Steel Frame Bundles

- Plastic end caps, anti-rust oiling, and film wrapping

- All export packaging compliant with ISPM-15 standards

Logistics Advantage:

- Competitive CIF/CFR rates

- Quick port-to-door delivery to Southeast Asia, India, Europe, and the Middle East

- Reinforced loading for anti-bending, anti-slippage, and anti-collision during shipment

10. Processing Services

- Bending (cold and hot-forming)

- Precision Cutting

- Threading & End Finishing

- Welding assembly (spools and elbows)

- Custom machining per drawings

11. Why Choose Womic Steel?

- In-house R&D & QA Lab

- Stable supply chain of raw materials ensures short delivery cycles

- Decades of metallurgical experience, especially in high-temperature alloys

- Full traceability and documentation for pressure equipment compliance

- One-stop solution provider for procurement, processing, and export of stainless steel pipe systems

For technical datasheets, pricing, and custom project quotations, contact Womic Steel today. We are ready to support your high-performance piping needs with precision, speed, and integrity.

Choose Womic Steel Group as your reliable partner for Stainless Steel tubes and unbeatable delivery performance. Welcome Inquiry!

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Post time: Apr-16-2025