Womic Steel is a leading manufacturer and global exporter of ISO 3183 L360NE seamless steel pipes, supplying high-performance carbon steel line pipes for natural gas and petroleum pipeline systems. Our products are manufactured in full compliance with the latest edition of ISO 3183 (Petroleum and natural gas industries — Steel pipe for pipeline transportation systems), specifically under the L360NE grade — a normalized, high-toughness line pipe.

1. Standard & Product Overview

Product Name: ISO 3183 L360NE Seamless Steel Pipe (SMLS)

Standard: ISO 3183:2019

Grade: L360NE

“L360” indicates minimum yield strength of 360 MPa

“N” denotes Normalized delivery condition

“E” requires enhanced toughness and full compliance with PSL2 level

ISO 3183 L360NE SMLS pipes are widely used in long-distance natural gas pipelines, oil and gas transportation, refinery piping, and high-pressure transmission systems, especially in low-temperature environments requiring high impact resistance.

2. Product Specifications

Outside Diameter: 21.3 mm (1/2") to 610 mm (24")

Wall Thickness: 3.2 mm to 50 mm

Length: Up to 12.5 meters (Fixed, SRL, DRL)

Ends: Plain End (PE), Beveled End (BE), Threaded + Coupling upon request

Surface Condition: Black (bare), Varnish-coated, or with anti-corrosion coating

Pipe Type: Seamless (SMLS) only for this grade

3. Chemical Composition (Typical Values – wt%)

|

Element |

Max Content (%) |

| Carbon (C) | ≤ 0.18 |

| Manganese (Mn) | 1.20 – 1.60 |

| Phosphorus (P) | ≤ 0.020 |

| Sulfur (S) | ≤ 0.010 |

| Silicon (Si) | ≤ 0.45 |

| Niobium (Nb) | ≤ 0.05 |

| Vanadium (V) | ≤ 0.10 |

| Titanium (Ti) | ≤ 0.04 |

| Carbon Equivalent (CEIIW) | ≤ 0.43 |

All chemical elements comply with ISO 3183 PSL2 requirements and are carefully controlled to ensure uniform weldability, toughness, and corrosion resistance.

4. Mechanical Properties

Yield Strength (ReH): ≥ 360 MPa (typically 370–450 MPa)

Tensile Strength (Rm): 460–760 MPa

Elongation (A5): ≥ 22%

Hardness (HV10): ≤ 250

Flattening / Bending Tests: Required and performed as per standard

5. Impact Toughness Requirements

L360NE is required to meet enhanced low-temperature toughness performance:

Charpy V-Notch Test: Minimum 27J avg at -40°C

Test Locations: Base metal, weld metal, and HAZ (if applicable)

Sampling Frequency: One set per test unit as per ISO 3183 PSL2

Test Orientation: Longitudinal or transverse depending on OD

6. Heat Treatment

All ISO 3183 L360NE seamless pipes are supplied in Normalized (N) condition:

Normalizing Temperature: 870–950°C

Controlled furnace cooling to achieve fine-grained structure and uniform mechanical properties

Heat treatment records maintained with full traceability.

7. Dimensional Tolerances (as per ISO 3183)

● OD Tolerance: ± 0.75% (min ± 0.5 mm)

● Wall Thickness: -12.5% / +15%

● Length Tolerance: -0 / +100 mm

● Straightness: 0.2% of total length max deviation

● End Squareness: ≤ 1.5 mm deviation

8. Non-Destructive & Destructive Testing

All pipes are subjected to 100% mandatory and selective testing:

● Hydrostatic Test: Each pipe tested at ≥ 95% SMYS

● Ultrasonic Testing: Full-body UT for lamination and longitudinal defects

● Eddy Current Test (optional): For surface flaws

● Visual & Dimensional Check: 100%

● Flattening / Bend / Drift Test

● Metallographic Examination & Grain Size Control

● Microstructure Etching for Banding Detection (optional)

9. Certifications & Documentation

Womic Steel ensures compliance with all major certifications:

● ISO 9001:2015 – Quality Management System

● ISO 14001:2015 – Environmental Compliance

● ISO 45001:2018 – Occupational Health and Safety

● EN 10204 3.2 Certification available upon request

● Third-party inspection: SGS, BV, DNV, TÜV, Lloyd's Register

● Test Reports Provided: Chemical analysis, mechanical tests, NDT results, heat treatment logs, and full traceability documents

10. Applications

High-pressure oil & gas transmission pipelines

Gas gathering & distribution networks

Refineries and LNG plants

Onshore & offshore pipeline installations

Slurry pipelines and industrial process piping

11. Production Cycle & Lead Time

Standard Lead Time: 20–35 working days

Urgent projects supported with accelerated rolling & dispatch

Raw materials pre-stocked from certified suppliers (Baowu, Valin, etc.)

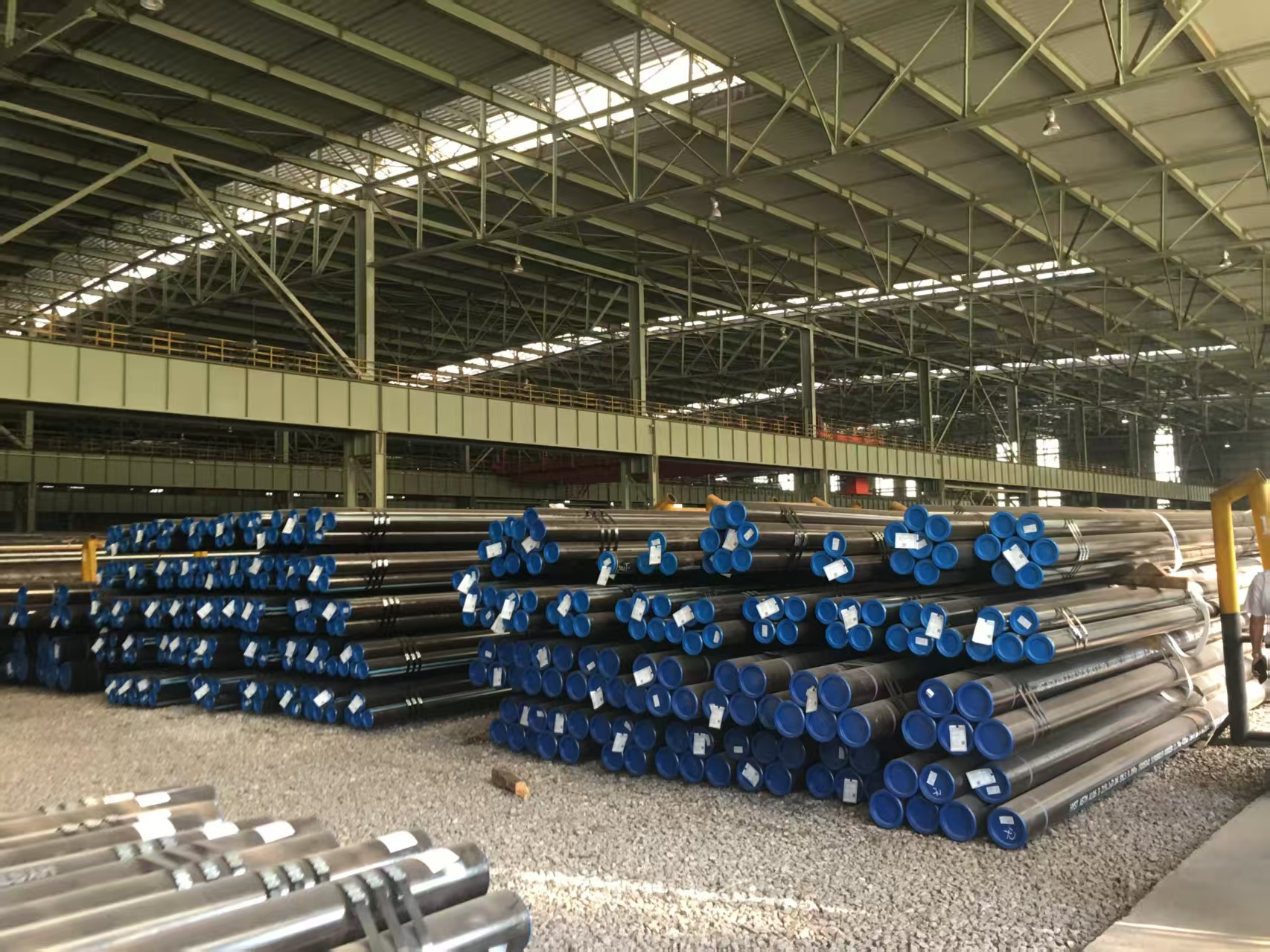

Monthly output: 5,000+ tons of SMLS pipes

12. Packaging & Marking

Marking: Inkjet or hard stamping includes size, spec, heat no., batch no., Womic logo, production date

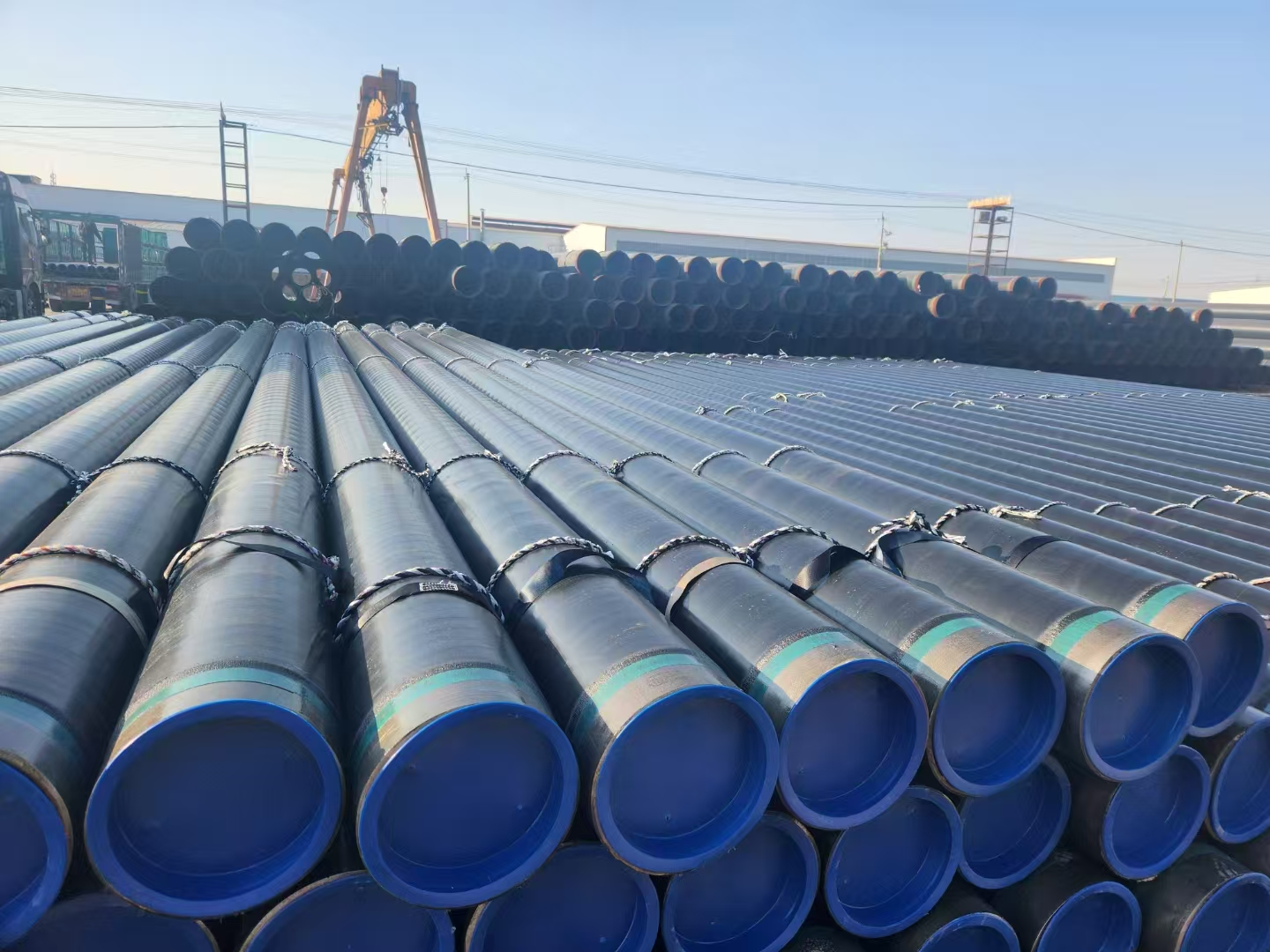

End Protection: Plastic caps or bevel protectors

Bundling: Hexagonal bundles with steel straps, max 2.5 tons per bundle

Wrapping: Waterproof paper + HDPE + steel frame wrapping for long-sea shipment

Tagging: Barcoded ID labels for digital traceability

13. Surface Protection & Coating

Womic Steel offers multiple external surface treatment options:

● Antirust Coating: Black lacquer, light oil film, or dry pre-blasted

● 3LPE/3LPP/2FBE Coating: Optional per ISO 21809 for pipeline corrosion resistance

● Internal Coating: Epoxy or cement mortar lining for water/oil flow

● Shot Blasting: Sa 2.5 finish for offshore / marine use

14. Why Choose Womic Steel

● Complete compliance with ISO 3183, EN, and project specifications

● Advanced SMLS rolling lines with full heat treatment capabilities

● In-house NDT and destructive testing labs

● Guaranteed raw material lead time and mill certification

● Coating lines & beveling shop for turnkey service

● Global shipment experience across 80+ countries

Choose Womic Steel Group as your reliable partner for Steel Plates,Structural Steels and unbeatable delivery performance. Welcome Inquiry!

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Choose Womic Steel Group as your reliable partner for SMLS Steel Pipes,Fittings and unbeatable delivery performance. Welcome Inquiry!

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568

Post time: Apr-17-2025