Product Overview

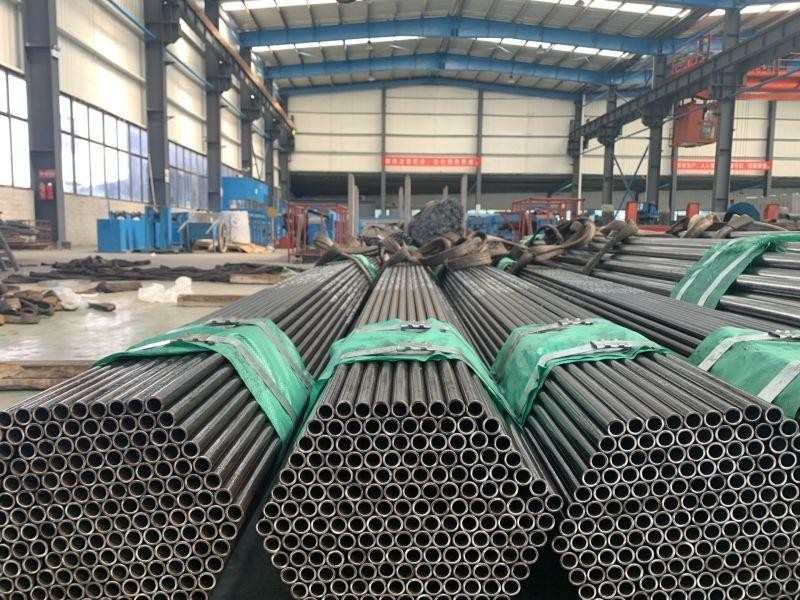

Womic Steel is a premier manufacturer of EN 10305-certified seamless steel tubes, designed for precision, strength, and durability across various industrial applications. Our seamless steel tubes are engineered to meet the strictest international standards, providing optimal performance for mechanical, structural, and fluid transport systems. From automotive engineering to hydraulic cylinders, Womic Steel ensures that each tube is crafted for excellence, guaranteeing exceptional quality and reliability.

Our EN 10305 seamless steel tubes are perfect for high-strength applications requiring precise dimensions, excellent mechanical properties, and robust resistance to wear and corrosion. These tubes are utilized across a broad range of industries, including automotive, machinery, fluid transport, and mechanical engineering, providing trusted solutions for precision engineering applications.

EN 10305 Seamless Steel Tubes Production Range

Womic Steel manufactures EN 10305 seamless steel tubes in a wide range of sizes and dimensions, ensuring versatility for various applications. The typical production range includes:

- Outside Diameter (OD): 6 mm to 406mm

- Wall Thickness (WT): 1 mm to 18 mm

- Length: Custom lengths, typically ranging from 6 meters to 12 meters, available upon customer request.

These tubes can be produced with specific requirements for custom diameters, lengths, and wall thicknesses based on client specifications and project needs.

EN 10305 Seamless Steel Tubes Tolerances

Womic Steel's EN 10305 seamless steel tubes are manufactured with a focus on precision. We guarantee the following dimensional tolerances for our products

|

Parameter |

Tolerance |

|

Outside Diameter (OD) |

± 0.01 mm |

|

Wall Thickness (WT) |

± 0.1 mm |

|

Ovality (Ovalness) |

0.1 mm |

|

Length |

± 5 mm |

|

Straightness |

Max 0.5 mm per meter |

|

Surface Finish |

As per customer specification (commonly: Anti-rust Oil, Hard Chrome Plating, Nickel Chromium Plating, or other coatings) |

|

Squareness of Ends |

± 1° |

EN 10305 Seamless Steel Tubes Delivery Conditions

The tubes are manufactured using cold drawing or cold rolling processes and are supplied in various delivery conditions based on specific customer needs. These include:

Table 1 — Delivery conditions

|

Designation |

Symbola |

Description |

|

Cold drawn / hard |

+C |

No final heat treatment after final cold drawing. |

|

Cold drawn / soft |

+LC |

Final heat treatment is followed by a suitable drawing pass (limited reduction of area). |

|

Cold drawn and stress relieved |

+SR |

After final cold drawing the tubes are stress relieved in a controlled atmosphere. |

|

Soft annealed |

+A |

After final cold drawing the tubes are soft annealed in a controlled atmosphere. |

|

Normalized |

+N |

After final cold drawing the tubes are normalized in a controlled atmosphere. |

|

a: In accordance with EN10027–1. |

||

EN 10305 Seamless Steel Tubes Chemical Composition

The EN 10305 tubes are produced from high-quality steel grades. Below is an overview of the standard material grades and their chemical composition:

Table 2 — Chemical composition (cast analysis)

|

Steel grade |

% by mass |

||||||

|

Steel name |

Steel |

C |

Si |

Mn |

P |

Sa |

Altotalb |

|

number |

|||||||

|

E215 |

1.0212 |

0,10 |

0,05 |

0,70 |

0,025 |

0,025 |

0,025 |

|

E235 |

1.0308 |

0,17 |

0,35 |

1,20 |

0,025 |

0,025 |

0,015 |

|

E355 |

1.0580 |

0,22 |

0,55 |

1,60 |

0,025 |

0,025 |

0,020 |

| Elements not quoted in this table (but see footnote b) shall not be intentionally added to the steel without the agreement of the purchaser, except for elements which may be added for the purposes of deoxidation and/or nitrogen binding. All appropriate measures shall be taken to prevent the addition of undesirable elements from scrap or other materials used in the steel making process. | |||||||

| a See option 2. b This requirement is not applicable provided the steel contains a sufficient amount of other nitrogen binding elements, such as Ti, Nb or V. If added, the content of these elements shall be reported in the inspection document. When using titanium, the manufacturer shall verify that (Al + Ti/2) ≥ 0,020. |

|||||||

Option 2: For the steel grades E235 and E355 a controlled sulphur content of 0,015 % to 0,040 % is specified to support machinability. It shall be obtained by resulphurizing the steel after maximum desulphurization or alternatively by using a low oxygen process.

Option 3: The chemical composition of the specified steel grade shall be such that it is suitable for hot-dip galvanizing (see e.g. EN ISO 1461 or EN ISO 14713-2 for guidance).

Table 3 and Table A.2 specify the permissible deviation of product analysis from the specified limits on cast analysis given in Table 2 and Table A.1

Table 3 — Permissible deviations of the product analysis from the specified limits on cast analysis given in Table 2

|

Element |

Limiting value for cast |

Permissible deviation of the product analysis |

|

C |

≤0,22 |

+0,02 |

|

Si |

≤0,55 |

+0,05 |

|

Mn |

≤1,60 |

+0,10 |

|

P |

≤0,025 |

+0,005 |

|

S |

≤0,040 |

±0,005 |

|

Al |

≥0,015 |

-0,005 |

EN 10305 Seamless Steel Tubes Mechanical Properties

The mechanical properties of EN 10305 seamless steel tubes, measured at room temperature, are as follows. These values depend on the steel grade and the delivery condition:

Table 4 — Mechanical properties at room temperature

|

Steel grade |

Minimum values for the delivery conditiona |

||||||||||||

|

+Cb |

+LCb |

+SR |

+Ac |

+N |

|||||||||

|

Steel |

Steel |

Rm |

A |

Rm |

A |

Rm |

ReH |

A |

Rm |

A |

Rm |

ReHd |

A |

|

name |

number |

MPa |

% |

MPa |

% |

MPa |

MPa |

% |

MPa |

% |

MPa |

MPa |

% |

|

E215 |

1.0212 |

430 |

8 |

380 |

12 |

380 |

280 |

16 |

280 |

30 |

290 to 430 |

215 |

30 |

|

E235 |

1.0308 |

480 |

6 |

420 |

10 |

420 |

350 |

16 |

315 |

25 |

340 to 480 |

235 |

25 |

|

E355 |

1.058 |

640 |

4 |

580 |

7 |

580 |

450e |

10 |

450 |

22 |

490 to 630 |

355 |

22 |

| a Rm: tensile strength; ReH: upper yield strength (but see 11.1); A: elongation after fracture. For symbols for the delivery condition see Table1 | |||||||||||||

| b Depending on the degree of cold work in the finishing pass the yield strength may nearly be as high as the tensile strength. For calculation purposes the following relationships are recommended:

—for delivery condition +C: ReH≥0,8 Rm; —for delivery condition +LC: ReH≥0,7 Rm. |

|||||||||||||

| c For calculation purposes the following relationship is recommended: ReH≥0,5 Rm. | |||||||||||||

| d For tubes with outside diameter ≤30mm and wall thickness≤3mm the ReHminimum values are 10MPa lower than thevalues given in this table. | |||||||||||||

| e For tubes with outside diameter>160mm: ReH≥420MPa. | |||||||||||||

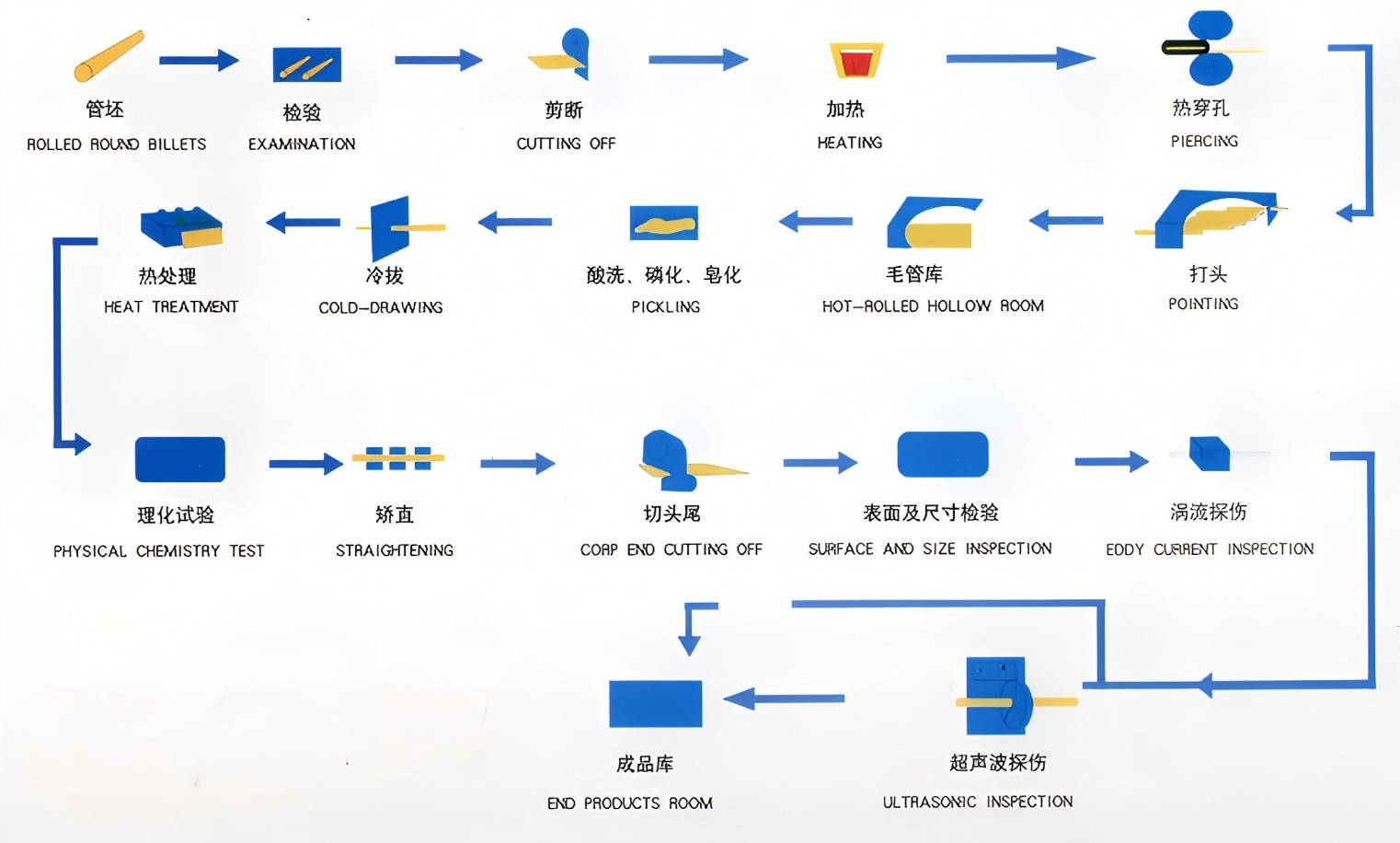

EN 10305 Seamless Steel Tubes Manufacturing Process

Womic Steel utilizes advanced manufacturing techniques to produce EN 10305 seamless steel tubes, ensuring high-quality, precision-engineered products. The process involves the following key stages:

- Billet Selection & Inspection:

The manufacturing process begins with high-quality steel billets, thoroughly inspected to ensure consistency and conformity with material specifications. - Heating & Piercing:

The billets are heated to an optimal temperature and then pierced to form a hollow tube, preparing them for further shaping. - Hot-Rolling:

The hollow billets undergo hot rolling to shape the tube, adjusting the dimensions for the final product. - Cold Drawing:

The hot-rolled pipes are cold drawn through dies under controlled conditions to achieve precise diameter and wall thickness. - Pickling:

After cold drawing, the tubes are pickled to remove any surface scale or oxide layers, ensuring a clean and smooth surface. - Heat Treatment:

The tubes are subjected to heat treatment processes such as annealing, which improves their mechanical properties and ensures uniformity. - Straightening & Cutting:

The tubes are straightened and cut to the required length, maintaining uniformity and precision. - Inspection & Testing:

Rigorous inspections, including dimensional checks, mechanical tests, and non-destructive testing (NDT), are conducted to ensure the highest quality standards.

Testing & Inspection

Womic Steel guarantees the highest levels of quality assurance and traceability through comprehensive testing procedures for EN 10305 seamless steel tubes. These include:

- Dimensional Inspection:

Measurement of outside diameter, wall thickness, length, ovality, and straightness. - Mechanical Testing:

Includes tensile tests, impact tests, and hardness tests to ensure the required strength and ductility. - Non-Destructive Testing (NDT):

Eddy current testing to detect internal defects, ultrasonic testing (UT) for wall thickness and structural integrity. - Chemical Analysis:

Material composition is verified using spectrographic methods to ensure that the material meets the required specifications. - Hydrostatic Test:

The pipe is subjected to internal pressure testing to ensure it can withstand operating pressures without failure.

Laboratory & Quality Control

Womic Steel operates a state-of-the-art laboratory equipped with advanced testing equipment to conduct in-depth quality checks. Our technical team performs routine inspections on every batch of EN 10305 seamless steel tubes to ensure compliance with strict international standards. We also collaborate with third-party testing agencies to provide independent verification of pipe quality.

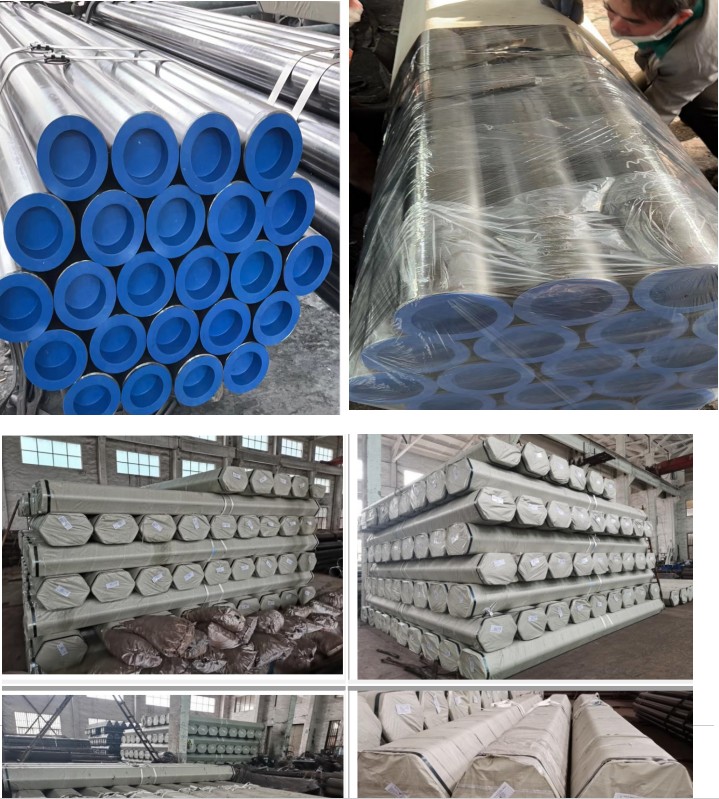

Packaging

The EN 10305 seamless steel tubes are packaged with care to ensure their safe transport and delivery. Packaging includes:

- Protective Coating:

Each tube is coated with a protective anti-corrosion layer to prevent rust and oxidation during transportation and storage. - End Caps:

Plastic or metal end caps are applied to both ends of the tubes to prevent contamination, moisture, or physical damage. - Bundling:

The tubes are bundled together securely with steel straps or plastic bands to maintain stability and prevent shifting during transport. - Shrink Wrapping:

Bundles are wrapped in shrink film to protect the tubes from dust, dirt, and other environmental factors. - Identification & Labeling:

Each bundle is labeled with product details, including steel grade, dimensions, batch number, quantity, and any special handling instructions.

Transportation

Womic Steel ensures timely and reliable global delivery of EN 10305 seamless steel tubes with the following transportation methods:

Sea Freight:

For international shipments, the tubes are loaded into containers or flat racks and shipped to any destination worldwide.

Rail & Road Transport:

For domestic and regional shipments, tubes are securely loaded onto flatbed trucks or containers and transported by road or rail.

Climate Control:

If necessary, we can arrange for climate-controlled transportation to protect the tubes from extreme environmental conditions.

Documentation & Insurance:

Full documentation for customs clearance, shipping, and tracking is provided, and insurance can be arranged for international shipments to safeguard against potential damage or loss.

Advantages of Choosing Womic Steel

Precision Manufacturing:

We maintain stringent control over all manufacturing processes to meet exact dimensional tolerances.

Customization:

Flexible options for tube lengths, surface treatments, and packaging based on customer specifications.

Comprehensive Testing:

Rigorous testing ensures that every tube meets the required mechanical, chemical, and dimensional standards.

Global Delivery:

Reliable and timely delivery, wherever your project is located.

Experienced Team:

Skilled engineers and technicians ensure the highest production quality and customer service standards.

Conclusion

Womic Steel's EN 10305 Seamless Steel Tubes are designed to deliver superior strength, reliability, and precision for a wide range of demanding applications. With our commitment to quality, advanced manufacturing, and customer satisfaction, we are the trusted partner for seamless tube solutions worldwide.

Choose Womic Steel for your EN 10305 Seamless Steel Tubes and experience high-performance products backed by unmatched expertise.

For more details, please contact us directly:

Website: www.womicsteel.com

Email: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 or Jack: +86-18390957568